While access to clean water is an essential prerequisite for quality of life, it is also a crucial factor for a country’s economic stability. What counts in beverage production is not only the volume of water available, but first and foremost its quality – and on a global scale there are sometimes considerable quality differences. For example, while valuable minerals like calcium and magnesium are often naturally present in drinking water available in Central European markets, in other parts of the world the raw water often contains unwanted naturally occurring constituents or impurities like arsenic and bromide or anthropogenic contaminants like pesticide residues, which necessitate significantly more elaborate treatment processes. In this case, purposefully targeted, technically sophisticated removal processes are needed in order to comply with statutory drinking-water regulations and the technical requirements posed for process water.

Water is life – and at the same time a resource increasingly coming under pressure. The global water crisis has already been tangible reality for a long time. It is a challenge we have to cope with now rather than tomorrow. Extreme weather events, industrial pollution and rising consumption levels collide with water’s reduced availability and deteriorating quality levels. And so, water has become a strategic factor, not least in the beverage industry. Krones has taken a holistic view for tackling the issue, starting with needs-based treatment and efficient use right through to sustainable water recycling.

Causes of the water crisis

Growing population and urbanisation

Growing cities and industries need more and more water, thus intensifying competition for clean water.

Climate change

Droughts, floods, glacier melt and the destruction of natural water stores, such as wetlands, result in a dramatic change of water availability.

Industrial and agricultural pollution

Pesticides, pharmaceutical residues, heavy metals – Many substances make their way into our groundwater and surface water. Persistent contaminants like PFAS (per- and polyfluoroalkyl substances) are of particularly high concern as they pose massive health risks.

Water consumption in agriculture

The Water Atlas 2025 is a German publication that provides information about the state of bodies of water and the challenges entailed for water supply. The Atlas states that around 70 per cent of the fresh water consumed worldwide is used for agricultural purposes, resulting in a conflict between the goals of food security and resource conservation.

What’s more, users’ requirements have been changing, posing yet another challenge for the beverage industry: Today, consumers expect far more than just impeccable quality. They want the water they drink to be not only safe and clean but to taste good into the bargain. They want water with a fresh flavour, a pleasant mouth-feel and often with an additional functional benefit like selectively added minerals.

Water Design as an added value

In order to help beverage producers meet all these expectations, Krones has launched its Water Design concept whose underlying philosophy is this: “Design water” instead of simply cleaning it. This concept is built around a holistic approach, which makes it possible to create a water that is not just hygienically safe but also perfectly matched to specific market requirements as far as its taste and functionality are concerned.

This Water Design concept is based on three key components:

- Meticulously crafted formulas

- Line technology fine-tuned to operate with maximised precision

- Selective addition of suitable minerals

That enables beverage producers to create an individually customised water, which meets regulatory requirements and consumer preferences, with kit that has been matched to regional raw-water qualities.

Component 1: Consultancy

From initial idea to line concept

A water’s sensory qualities are crucially influenced by the minerals it contains, which determine its mouth-feel, freshness and taste intensity. While European consumers prefer natural waters that are rich in minerals, people in many Asian markets are increasingly reaching for what is called purified water, that is, almost completely demineralised water. “Taste ideals vary widely across the globe. The real artistry lies in designing a water that is not only technically impeccable but also scores highly in terms of sensory experience,” says Jörg Berger, a member in Krones’ sales team focussing on water treatment.

That is why in its Water Design Center in Neutraubling, Krones relies on innovative processes and the knowledge of numerous experts, including Jörg Berger who is a trained water sommelier. Here, tailor-made formulas are created – no matter if for premium branded waters or functional drinks with specific requirements. Products that are perfectly balanced in terms of both taste and health benefits can be designed by selectively adding certain ingredients. Krones has been expanding this competence centre for water analysis since early 2025. State-of-the-art analytical equipment like an ion chromatograph now enable the centre’s team to examine customer samples directly on the spot fast and accurately – no need to involve external laboratories. In close collaboration with our own water sommeliers, we have created a place where sensory training, taste optimisation and product development go hand in hand.

The sensory aspect is thus the first pillar in modern water design. Mind you, taste is only one aspect of water quality. The next pillar is systematic water treatment.

Component 2: Equipment

Systematic water treatment

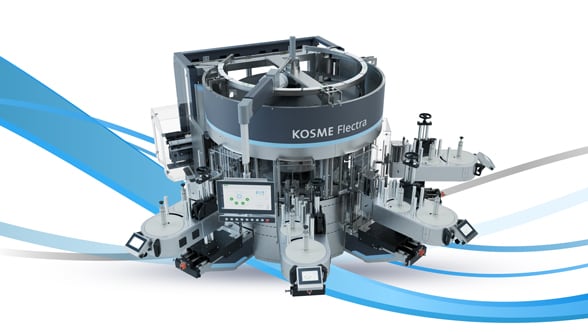

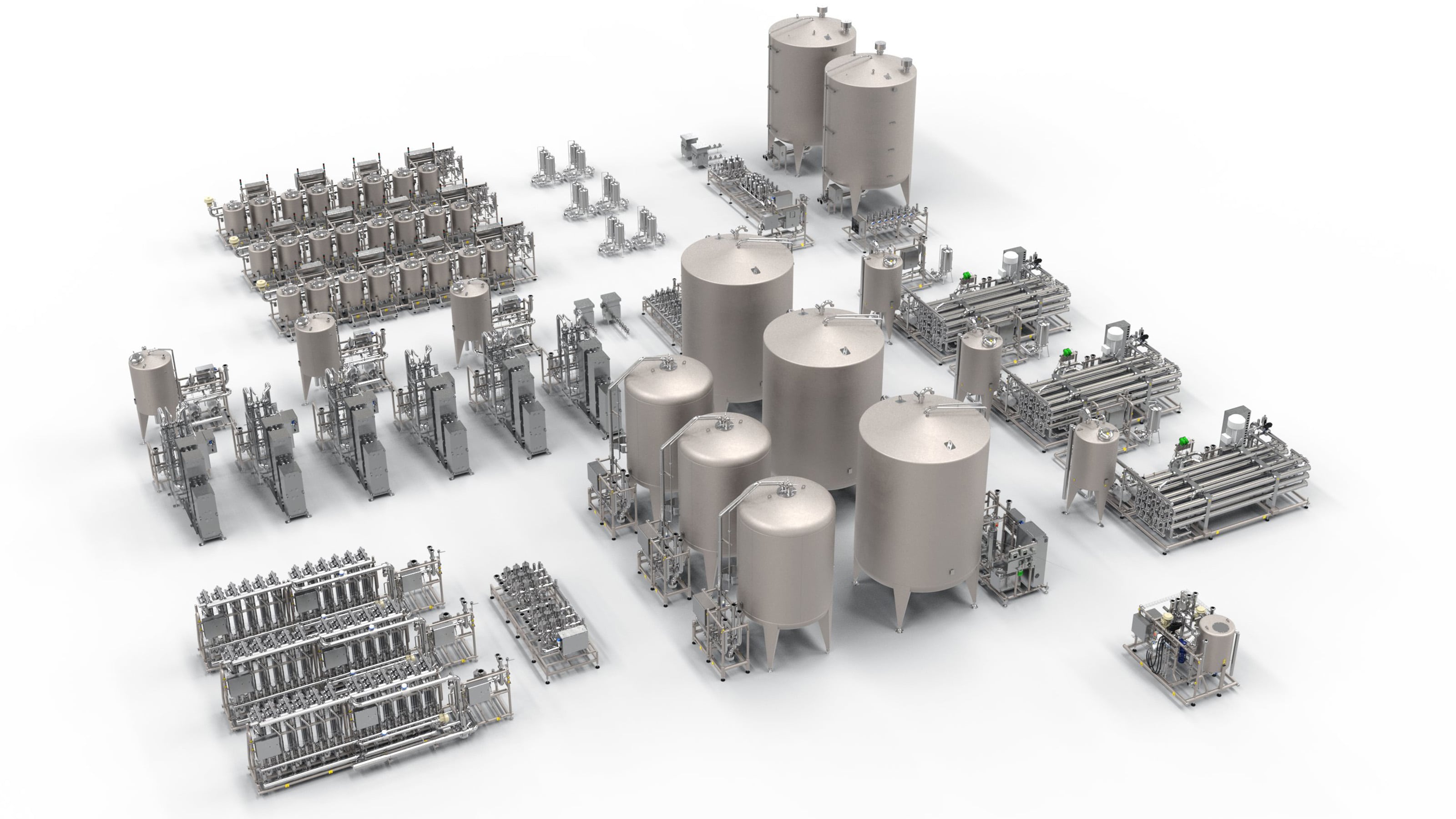

Comprehensive treatment of the raw water constitutes the technical foundation for any water design, which must in each case be matched to the source, target market, end product and the production conditions involved. “The basic rule here is that there is no one-fits-all solution for water treatment,” says Stefan Höller, Head of Product Management and Development for Processing Units at Krones. “Depending on the geological characteristics and the source of the raw water to be treated, the requirements involved may vary considerably even within the same region.” And that is precisely where the Hydronomic comes in: Krones’ modularised solution for water treatment extends far beyond any conventional system, opening up new scope for product design. “It is aimed at enabling producers all over the world to respond flexibly to a wide variety of raw water qualities, to translate global brand standards into perfect reality while at the same time increasing operational efficiency,” emphasises Stefan Höller.

MDS: Mineral dosing station

Hydronomic MDS

Thanks to the use of a mineral dosing station – in brief MDS module – you can remineralise your water exactly in line with your own formulas – for the highest possible flexibility and individualisation of your product.

EDI: electro-deionisation

EDI module

Electro-deionisation (EDI) allows you to produce ultra clean, deionised water which then merely requires the addition of the desired minerals. The use of this kind of additional EDI module is particularly recommended in cases where the untreated water quality fluctuates. This is particularly important in the manufacture of still table water where there must be no deviation in the mineral composition of the product.

RO: reverse osmosis

Hydronomic RO

Variable output regulation and automatic yield control ensure the highest possible flexibility and minimise scaling on the membranes. The membranes can also be flushed with permeate to minimise scaling and biofouling.

UF: ultrafiltration

Hydronomic UF

- The individual control of the filter modules in the Hydronomic UF guarantees uninterrupted production. Only ultrafiltrate is used during backflushing.

- Filtration performance: up to 150 m³/h

- Rinsing water consumption: max. 36 m³/h

- Yield: Up to 99.9 %

MF: media filtration

Hydronomic MF/GAC

- Filtration performance: up to 120 m³/h

- Yield: up to 99.5 %

Key components of the Hydronomic include activated-carbon filters and reverse-osmosis units. Activated-carbon filtration (Hydronomic GAC) can be relied on to remove organic compounds as well as free chlorine and disinfectant by-products, thus constituting an essential step for ensuring odour- and taste-neutrality. Reverse osmosis (Hydronomic RO) serves to demineralise raw water and remove micro-contaminants like heavy metals, pesticides or other residues from agriculture. It is indispensable when treating heavily polluted raw water, in particular. Above and beyond these two, further modules can be integrated:

- MF: media filtration for removing iron and manganese, for example

- UF: ultrafiltration acting as a reliable barrier against microbiological contaminants

- UV: UV disinfection without the use of chemicals

Substance of choice: ozone

Additionally, hygienic safety plays a key role in the downstream process, especially when filling still water into PET bottles. It is here that Krones’ Ozonomic technology comes in, taking advantage of ozone’s disinfecting effect in order to ensure maximised microbiological safety. Ozone dissolved in water reliably eliminates microorganisms like bacteria and viruses and then swiftly breaks down into oxygen, leaving no chemical residues. This characteristic renders it particularly suitable for products which must retain both taste-neutrality and microbiological stability.

One crucial aspect of ozonisation is that it disinfects not only the beverage itself but also the packaging: When handling PET bottles, the water serves as the medium that carries ozone into the bottle, thus effectively disinfecting the head space and the inside of the cap as well. This hygienisation method is gentle on the product and does not need any additional chemical cleaning processes in the bottling line.

Hydronomic and Ozonomic vividly demonstrate that what used to depend on regional conditions can nowadays be systematically planned. Water quality in itself is no longer the sole determinant factor – state-of-the-art treatment technologies enable producers to perfectly match it to ongoing trends. And that goes not only for water but for all beverages across the board, as vividly demonstrated by beer. In Pilsen, for example, the soft, low-mineral water made it possible to create the famous pilsner beer. The water in Munich, by contrast, is considerably harder, which is why without water treatment only dark beers could traditionally be made there. State-of-the-art treatment methods nowadays enable breweries to adjust their water’s quality and thus to brew a diversified range of beers, irrespective of where they are located.

And that paves the way to the third pillar: targeted design of taste and function.

Component 3: Mineralisation

Purposefully tailored taste and function

One of the key elements in water treatment today is remineralisation. That is especially vital for water coming from the reverse-osmosis module, which removes almost all dissolved constituents (both unwanted substances like arsenic and valuable minerals like calcium and magnesium). Afterwards, a dosing system can be used to remineralise this water with individually matched blends – accurately metered in a stable, reproducible process.

In Asian markets there is growing demand for waters that serve a specific function, that have a pH value of 9, for example. Such alkaline waters are said to offer health-promoting benefits, like binding free radicals or having a positive effect on the acid-base balance. Hydrogen carbonate, in turn, has an acid-binding effect and can help alleviate heartburn. Calcium and magnesium may support bone stability and the body’s mineral balance. Silicate – also known as “the wellness mineral” – imparts a soft flavour and is regarded as beneficial for skin, hair and nails. “Not only does it give the product a distinctive sensory profile, it also opens up strategic scope in marketing,” says Jörg Berger.

Water as strategic design element

Whether it’s the involvement of trained water sommeliers in the Water Design Center, modularised treatment systems like the Hydronomic or precise mineral dosing: Krones’ holistic approach shows that water is much more than just a raw material, it is a strategic design element. Interlinking water quality, sustainability and technological efficiency enables beverage producers to not only reliably comply with statutory requirements but to systematically respond to regional market needs and consumer expectations as well. With its comprehensive Water Design concept, Krones supports companies in defining their brand identity not least through a distinct profile for their water. From lab to line, from source to bottle: At Krones, water is designed in full awareness of all the factors involved.

HydroCircle: wastewater turned into a resource

Water Design doesn’t stop at taste, function and quality. Sustainable use of water along the entire production process is increasingly becoming yet another strategic success-driving factor. With its HydroCircle concept, Krones offers a solution that extends far beyond traditional water treatment: a smart water management system, which systematically converts production wastewater into new process water, thus keeping it in a closed circuit. “Every litre of water that we don’t use in the wet end and for beverage production is a litre that doesn’t have to be expensively treated as wastewater,” emphasises Jörg Berger.

The HydroCircle concept integrates various advanced technologies, including biological wastewater treatment (anaerobic and aerobic), biogas production, multi-stage reverse osmosis and salt recovery by means of electrodialysis. In this way, even severely contaminated production wastewater can be converted into high-quality process or service water – to be used, for instance, for cleaning and cooling, or even channelled back into production. Downstream sterilisation by means of UV or ozone ensures microbiological safety. Not only does that reduce water consumption, it also cuts operating costs and renders companies less dependent on resources that are in short supply – a genuine competitive advantage, especially in regions with high water stress.