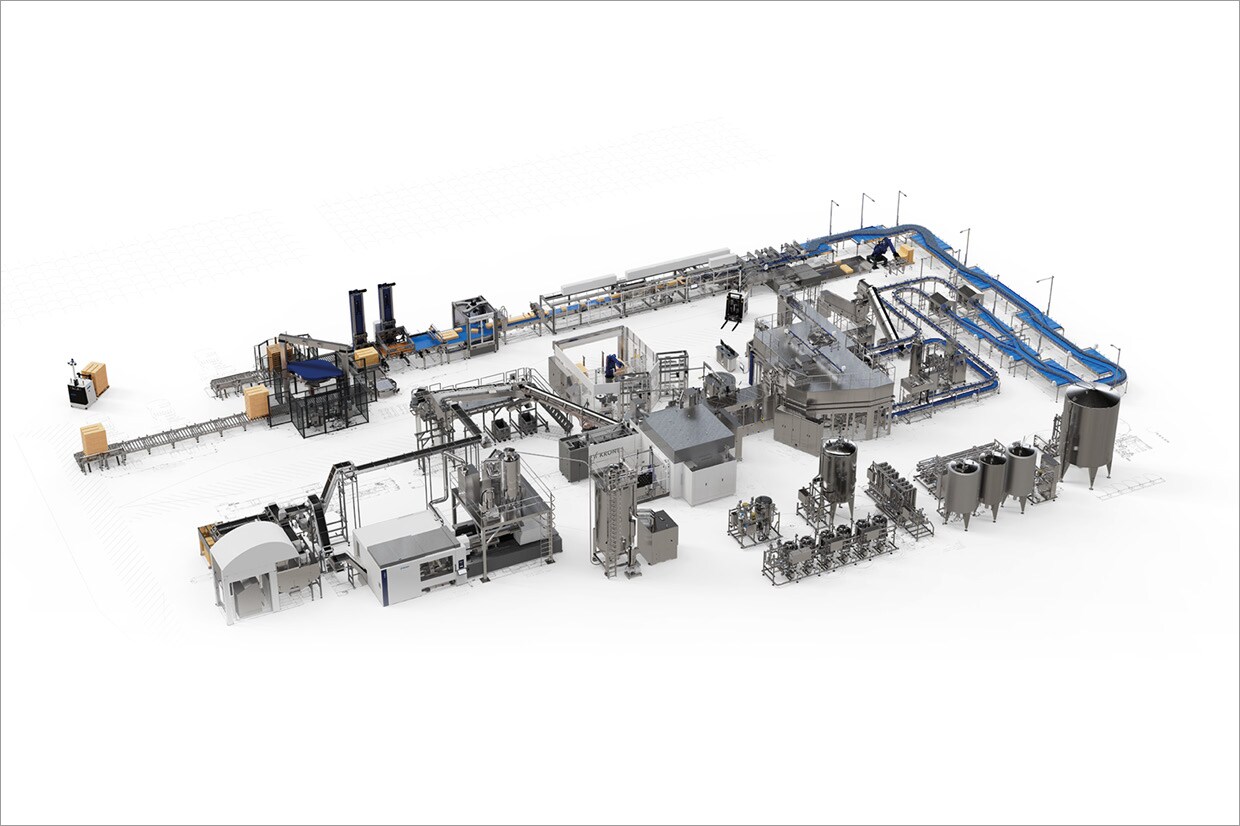

Ingeniq is a new line concept that was designed as the answer to the most frequent questions (or rather requests) we’ve gotten from customers recently. And it translates what Krones presented as a vision at drinktec 2022 into shopfloor reality: a line that couples low total cost of ownership with consistently high efficiency.

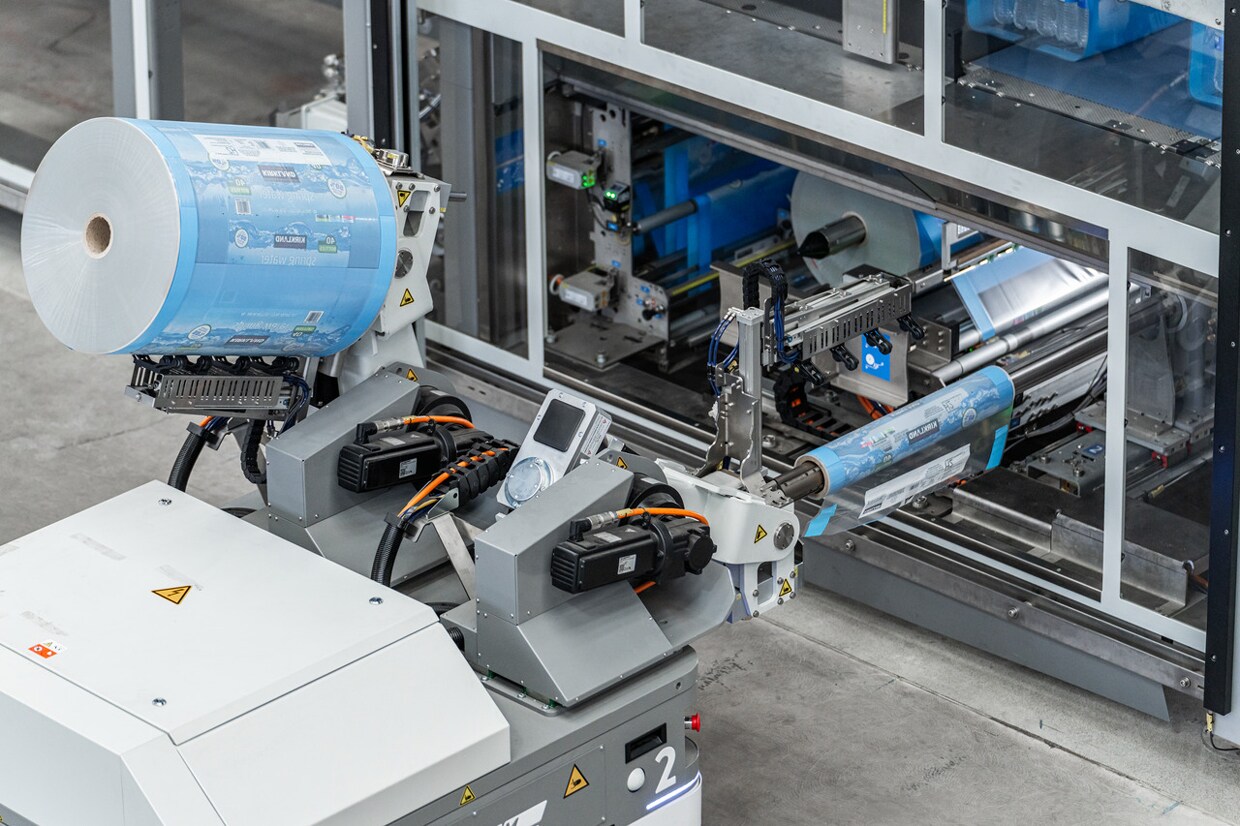

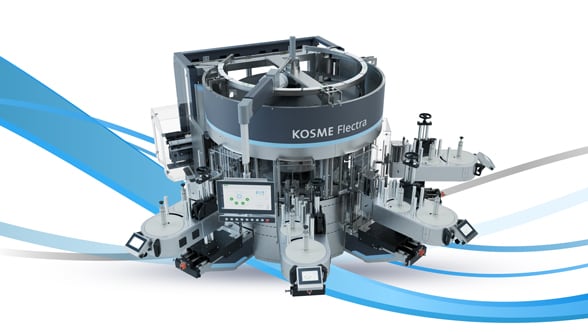

The system consists of modular and standardized components that leverage robotics and artificial intelligence in a well-thought-out design that reduces the overall complexity of the line layout. “At Krones, we know that our success depends on our customers’ success. That is why we have taken this line concept a step further, forging an alliance with the customer and actively assuming joint responsibility for the entire life cycle – that is something that’s never been done before,” explains Markus Tischer, Member of the Executive Board of Krones AG responsible for International Operations and Services.