Flexible plastics recycling: We close the loop for PET, PE, PS and more

The days when PET was the only – or at least almost the only – plastic recycled to a high standard are long gone. In addition to PE, PP, PS, and their sub-forms, it is now possible to recycle countless other plastics. This is precisely what we at Krones Recycling aim to do: to contribute to the circular economy with systems that combine sustainability and cost-effectiveness.

In summary

- Recycling of PET, PP, HDPE, LDPE and PS

- Manufacture of a range of material qualities – for PET up to food grade in accordance with FDA and EFSA

- Energy-saving, direct further processing to produce films, preforms or pellets (optional)

In the form of a bottle for all kinds of beverages or as a bowl for fruit and vegetables: polyethylene terephthalate (PET) is one of the most popular plastics for food packaging as it is one of the most durable plastics while also being easy to shape and highly resistant to moisture.

Thanks to our decades-long experience in the packaging industry, Krones has been successfully completing the recycling loop for PET beverage bottles since 2009 with its Recycling division. Even demanding challenges such as yellowing, discolouration, or black specks are reliably mastered.

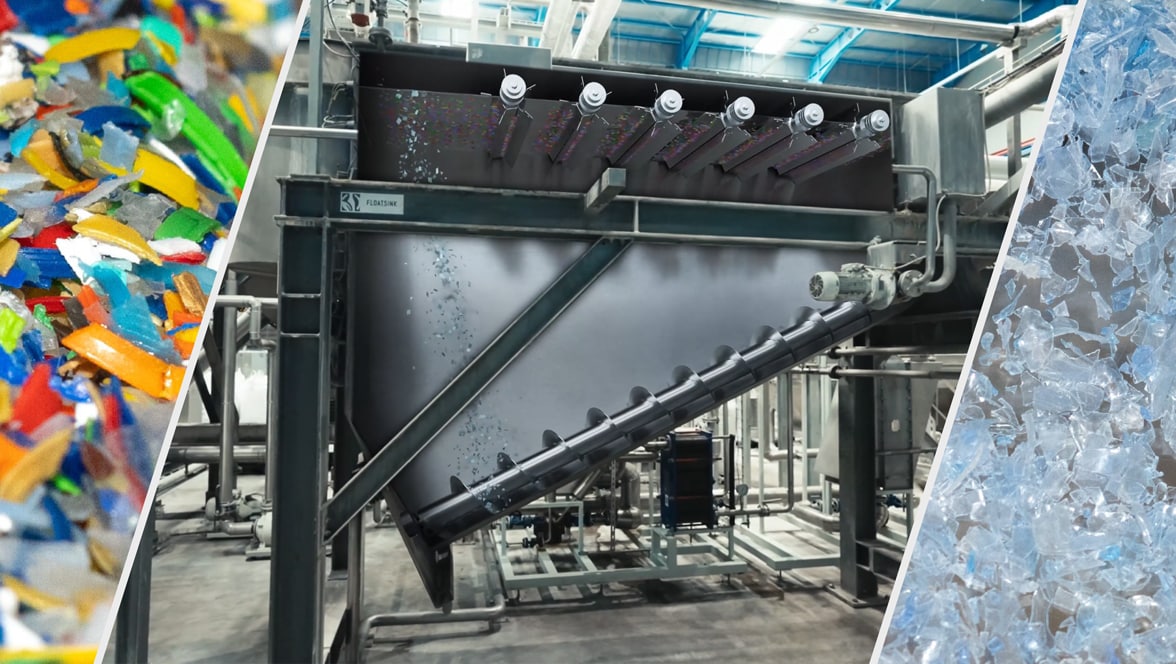

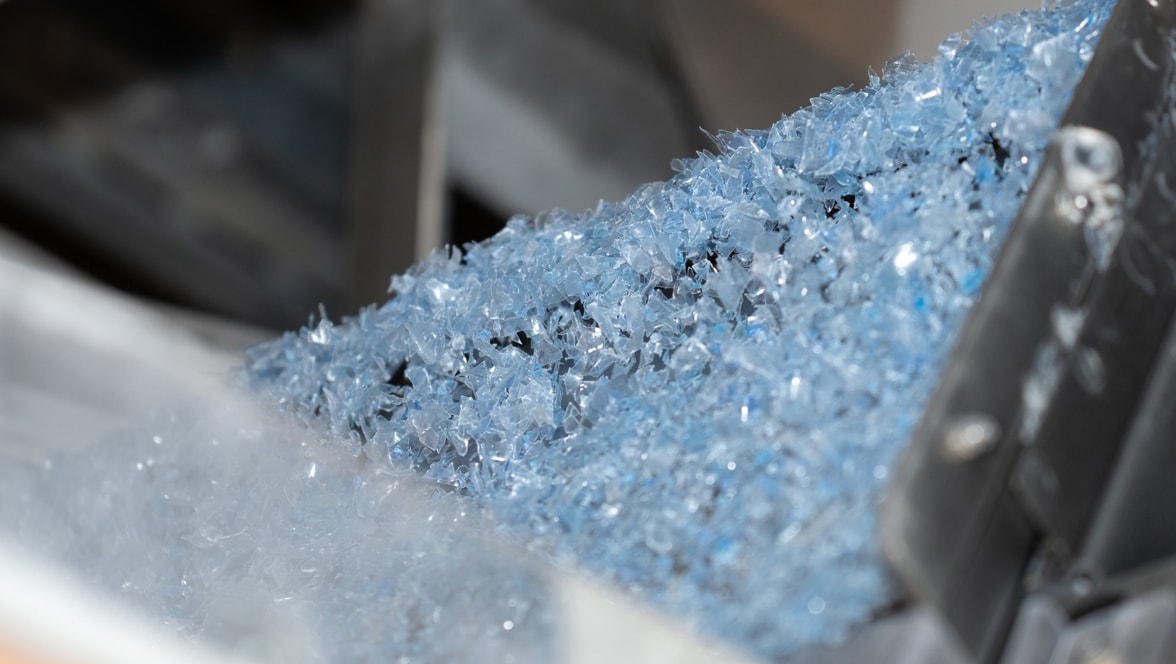

The portfolio ranges from individual modules for grinding, washing, sorting and decontaminating to complete turnkey solutions for PET recycling. The energy-efficient processing of the flakes into preforms, films, or pellets can be seamlessly integrated – for sustainable and economical recycling.

Polypropylene is also frequently used both in food packaging and in other industries. Typical applications include bottle caps, reusable containers, thermoboxes, heat-retaining containers, and heat-resistant films. Its properties, such as high thermal and chemical resistance, make PP the ideal choice for demanding packaging solutions.

During recycling, PP must be handled very gently due to its susceptibility to breakage – no problem for Krones Recycling units that operate at the required slow speed. Even the comparatively low bulk density does not pose a challenge thanks to adapted conveyor units.

What do containers for cleaning agents or hygiene products have in common with food storage containers? A plastic characterized by toughness, durability and high chemical resistance is preferred for all of them: high-density polyethylene (HDPE). When recycling HDPE containers, our washing module reliably prevents foam forming from cleaning agent residues by applying a gentle process and using specially formulated additives. Labels and information stickers are also removed completely.

Low-density polyethylene (LDPE) is mostly found in everyday use as transparent film. As such, it requires a special recycling process. On the one hand, LDPE has a low bulk density, something which Krones Recycling can compensate for with its adapted units and lower throughput. On the other hand, various factors must be taken into account during washing, because: LDPE film is often printed or glued, meaning more ink and adhesive must be removed during washing. The degree of contamination also varies – shipping films, for example, are only slightly contaminated, whereas lightweight packaging taken from household waste is usually more heavily contaminated. Depending on requirements, the Krones Recycling washing module can therefore also be used for more intensive washing including hot washing. Our systems can then be used to dry the washed films even if wrinkling has formed.

Solid polystyrene (PS) is frequently used to pack dairy products, while its transparent form is used for CD covers, for instance. As solid polystyrene is even more brittle than PP, special care must be taken when grinding and washing it.

In foamed form, as expanded polystyrene (EPS) or extruded polystyrene (XPS), it is often used as a box for transporting food and pharmaceuticals or as a foam tray for takeaway food thanks to its excellent insulating properties. During the washing process, foamed PS absorbs a great deal of moisture, which our technology then squeezes out in a directed manner so as to effectively prevent it from being carried over.

At our Recycling Technology Center, we provide an opportunity to test materials under realistic conditions with our mechanical recycling process – even for individual queries and requirements.

In addition, our systems allow us to offer simplified washing, which can be used as a preparatory step for further processes such as chemical or so-called “advanced recycling”.