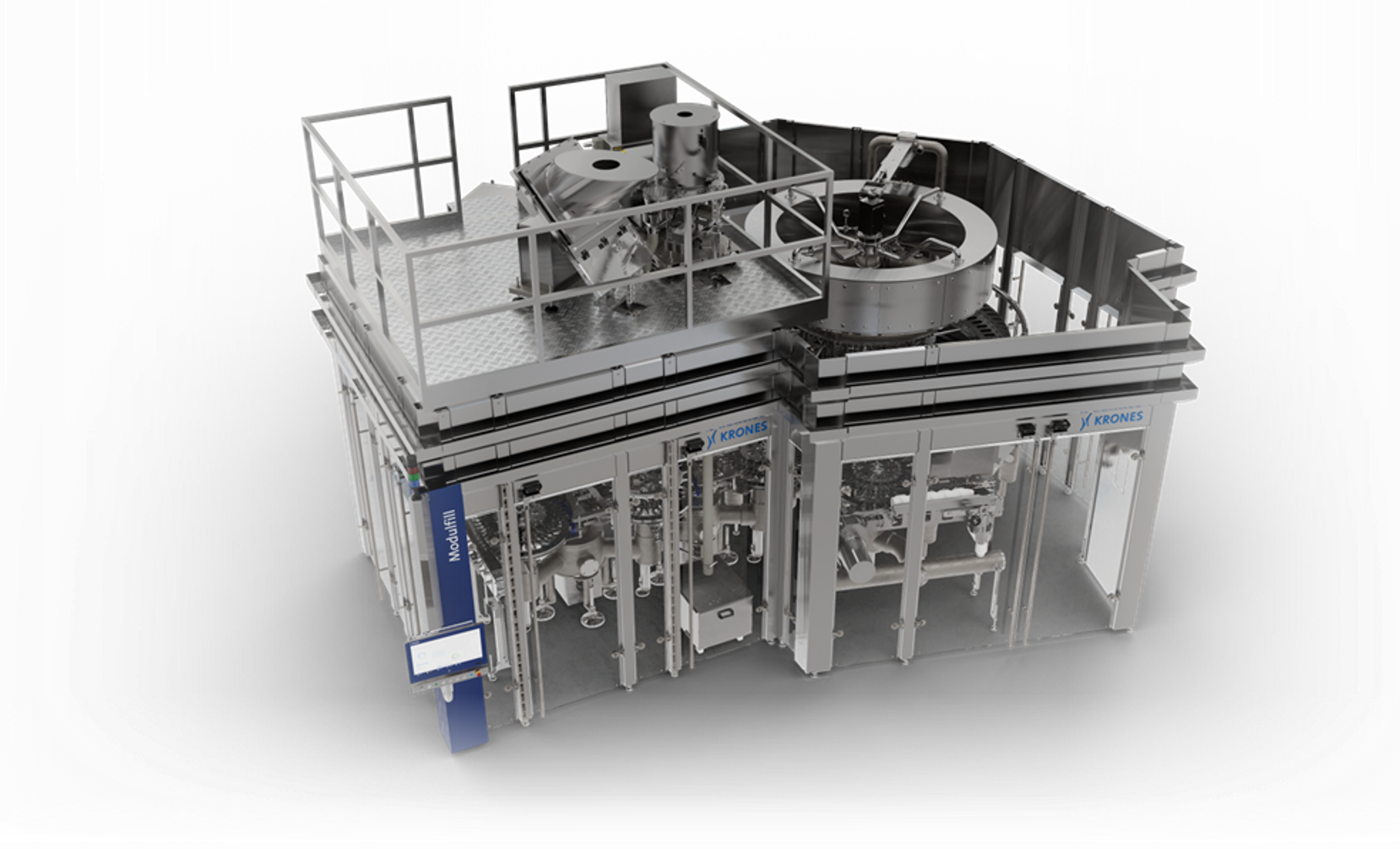

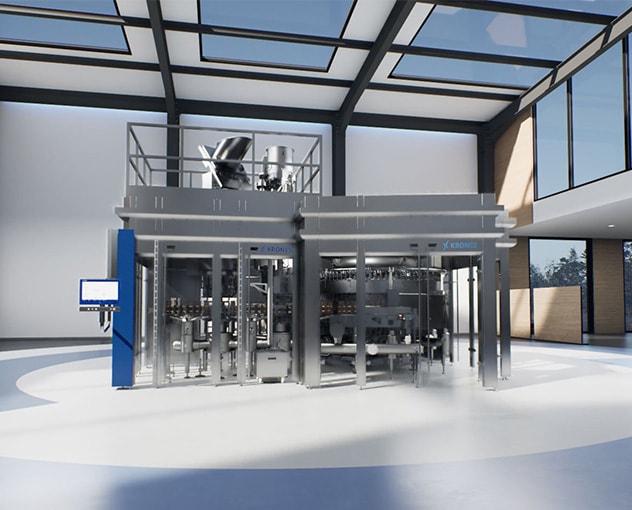

Filling beer, carbonated soft drinks (CSD) or water into glass bottles – with the same filling valve

Electronic height filler as an all-rounder

The Modulfill HES* is a true all-rounder – as beer, carbonated soft drinks or water can all be successfully filled with the same filling valve. Product-specific filler adjustments ensure unmatched filling quality on the market, with outputs of up to 78,000 containers per hour. The Modulfill HES can also be optimally combined with machines from the Krones range of cappers.

Carbonated soft drinks (CSD) and water

- Solution individually adjusted to the product and in line with the microbiological and hygiene requirements

- Highest flexibility thanks to multifunctional MultiGuide Base clamping starwheels

Beer

- Lowest possible oxygen pick-up through multiple pre-evacuation steps with intermediary CO2 flushing

- Latest vacuum technology

- Intelligent process gas control system: automatic quality control and process optimisation

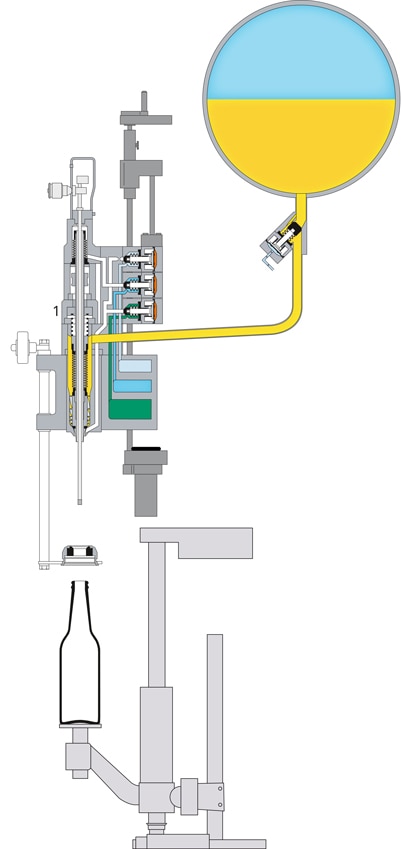

The filling system

- Electronical determination of the fill level via probe

- End of filling after probe signal

- Low-oxygen filling through several pre-evacuation steps with intermediary CO2 flushing

- Electropneumatic filling valve

- Two filling speeds

Functional principle of the valve

First the glass bottle is pressed on and optionally evacuated multiple times. The filling process will start as soon as the same pressure prevails in the ring bowl and the glass bottle. Two different filling speeds guarantee optimum flow. The valve closes if the liquid flowing in touches the probe mounted on the filling tube. After a settling phase, the pressure in the head space of the glass bottle is reduced via a snifting valve and the filled product exits the machine.

Conductivity > 50 µS/cm

Viscosity < 10 mPa·s

Pulp ≤ 0.4 mm/proportional< 10 %

Fibres 1 x 5 mm/proportional < 5 %

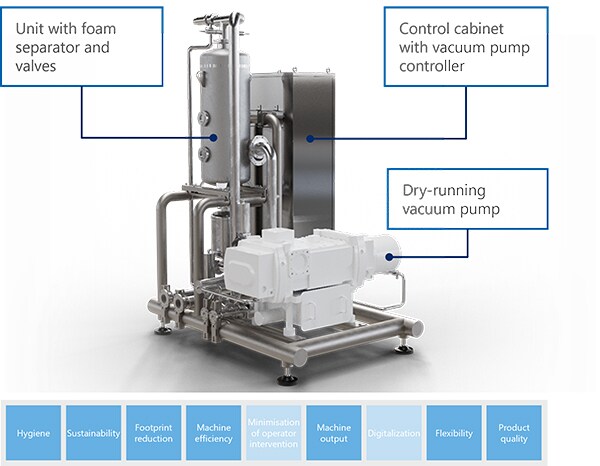

For filling oxygen-sensitive products

Optional: pump unit with dry-compressing vacuum pump

The unit has been designed in the usual Krones quality and is viewed as an integral part of the machine. Using a dry-compressing vacuum pump means that not only can production be more sustainable, but a higher product quality can also be achieved during the filling of oxygen-sensitive products.

Benefits to you

- Achievement of lower vacuum values in the filling process

- Optimum hygiene conditions in the machine, since the piping and foam separator are integrated into the CIP circuit as usual

- Significant minimisation of the water consumption during production

- Reduced energy consumption by up to 25 percent*

* During the ongoing production, compared to a conventional liquid-ring vacuum pump with the same intake capacity

Design with dry-compressing vacuum pump

For reducing the absorption of CO2 and oxygen

The HES filling valve combined with a dry-compressing vacuum pump impresses with its numerous benefits: A newly designed arrangement of the individual functions in the filling valve leads to optimised flows. Combined with the “lower” vacuum values, the Modulfill HES sets entirely new standards in conventional beer filling in terms of oxygen absorption and CO2 consumption.

Benefits to you

- Less oxygen pick-up and therefore a longer shelf life for the beer

- Lower CO2 consumption, which leads to resource savings during production

Optional: automatic probe adjustment and automatically positioned CIP cups

Automated probe adjustment and the CIP cups complement one other perfectly, meaning that manual operator intervention at the filling valve is no longer necessary both for type change-overs and cleaning. The automatic CIP cup is installed as part of the lift cylinder. A mechanical swivel mechanism swivels the container plate backwards and moves the CIP cup against the centring bell and the filling valve, creating a closed cleaning cycle.

Benefits to you

- Available from a machine pitch of 87 millimetres

- More compact machine size possible with the same output

- Automatic and reproducible change-over when changing types with a different fill level

- Cleaning and change-over times reduced to a minimum

- Improved machine hygiene and product quality: No risk filling valve and probe becoming recontaminated when the operator removes the CIP cups

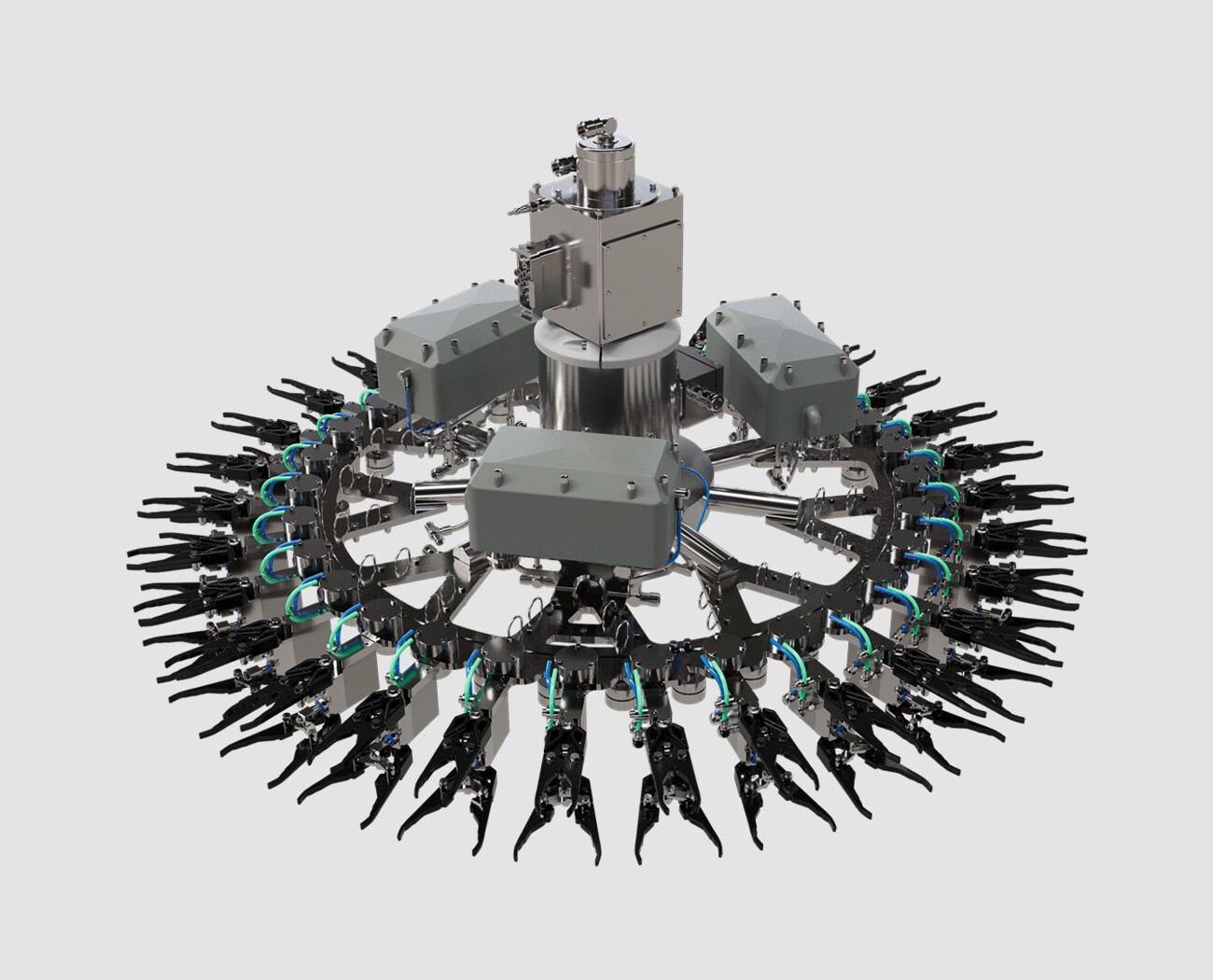

MultiGuide Base clamping starwheels

The name already suggests it: Krones MultiGuide Base is a veritable all-rounder. The multifunctional clamping starwheel processes almost all glass bottle formats – and thus combines all the handling parts that are otherwise required for the various container types and sizes. The "one for all" principle saves a great deal of operating effort, time during change-overs and space in the warehouse - a real "win-win-win" situation.

Benefits to you

- Increased station performance compared to mechanical clamping starwheel

- Active rejection of containers

- Integration into the Krones pitch-adjusting for base handling

- Minimisation of wear

The benefits

Best technological values

- Less oxygen pick-up and therefore a longer shelf life for the beer

- When using a dry-compressing vacuum pump:

- lower CO2 and water consumptions, thus leading to resource savings during production

- Achievement of lower vacuum values in the filling process possible

IT and digitalization

- Oxygen monitoring incl. process gas control

- Revealing CO2 savings potential

- Automatic optimisation of flushing and vacuum times

- Automatic and reproducible change-over when changing types with a different fill level

- Change-over times reduced to a minimum thanks to the use of multifunctional MultiGuide Base clamping starwheels

Combined with Krones capping technology

- Crowner:

- More output

- More automation thanks to automatic crown emptying system

- Aluminium roll-on capper: Shortened change-over times thanks to quick-change heads

- Mechanical or servo-controlled screw capper for screw caps and press-on caps

Inspired by the challenge of the future in terms of sustainability and Krones' corporate goals, we have been working on taking our Modulfill HES for beer filling to the next level in terms of flexibility, sustainability and machine output.

Inspired by the challenge of the future in terms of sustainability and Krones' corporate goals, we have been working on taking our Modulfill HES for beer filling to the next level in terms of flexibility, sustainability and machine output.