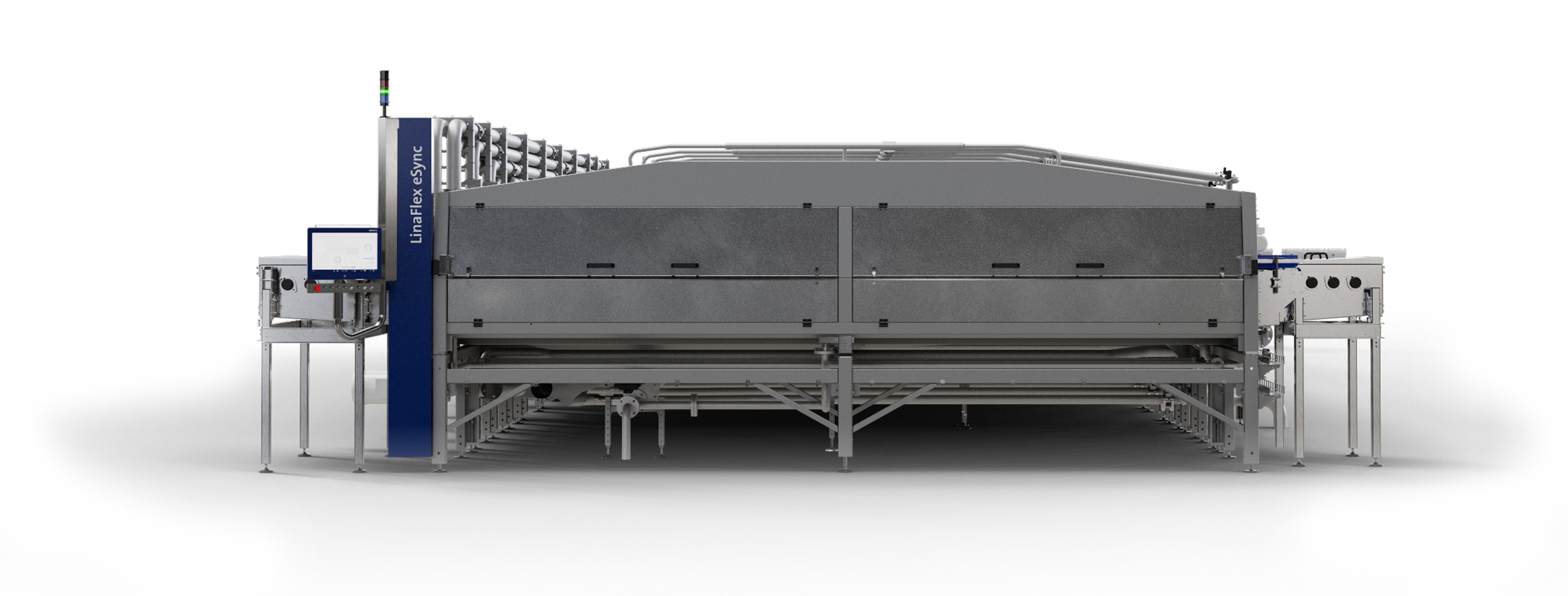

The LinaFlex eSync - Pasteurisation reinvented

For beverage manufacturers, product quality is a top priority - because only perfect products ensure that consumers are satisfied and happy to return. The tunnel pasteuriser LinaFlex offers a pasteurisation process with precise PU control and an efficient use of resources - all while requiring less space, being less complicated and offering better accessibility.

At a glance

- Combined buffer function for the entire line (up- and downstream)

- Less space required due to the continuous, one-lane conveyor

- Up to 40 percent in the wet end,

- up to 25 percent in the entire line.

- Few components and drives, no back-up switch

- Less pressure on the lateral surfaces of cans

- Dynamic adjustment of the pasteuriser to current filler speed

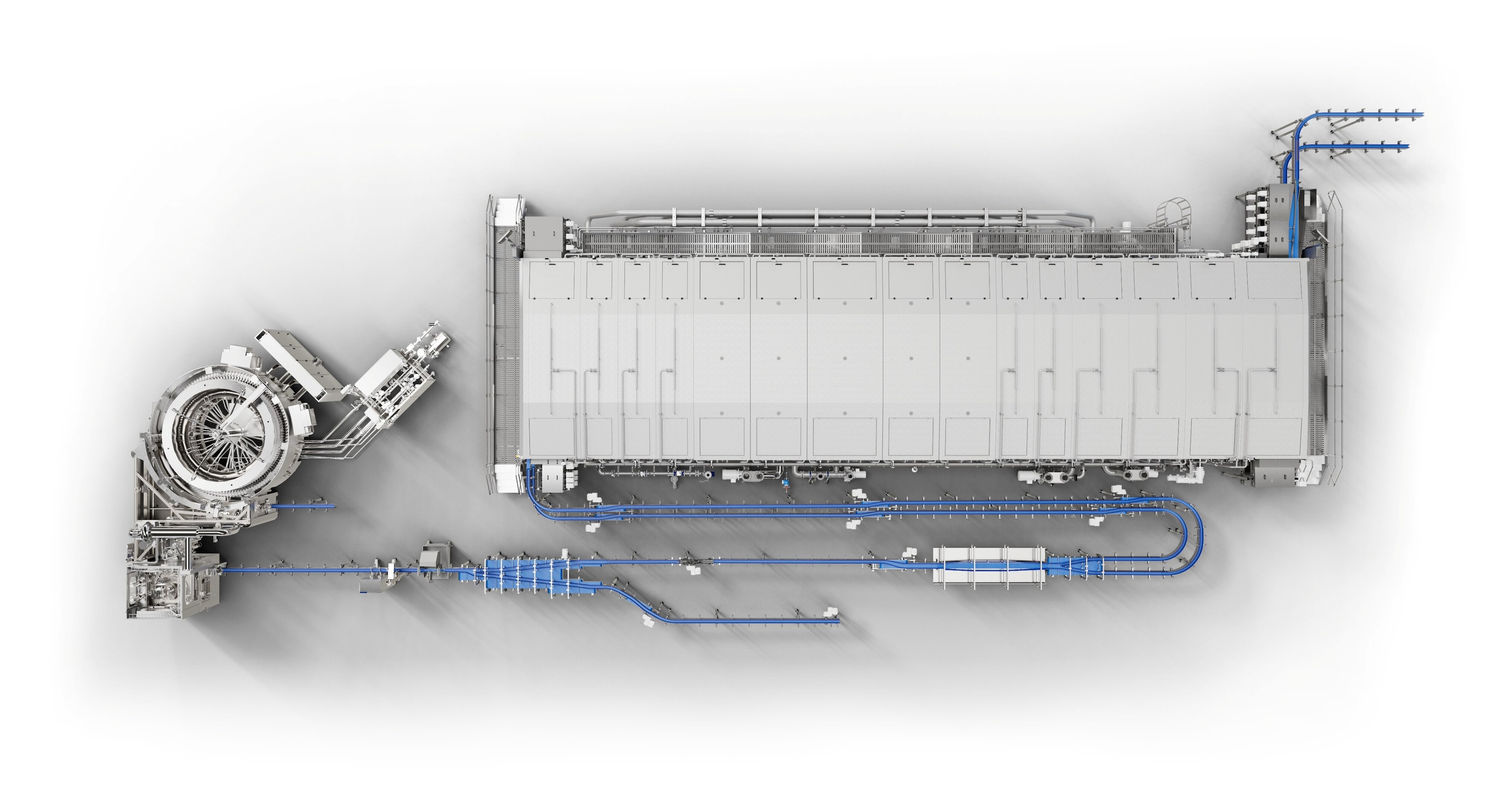

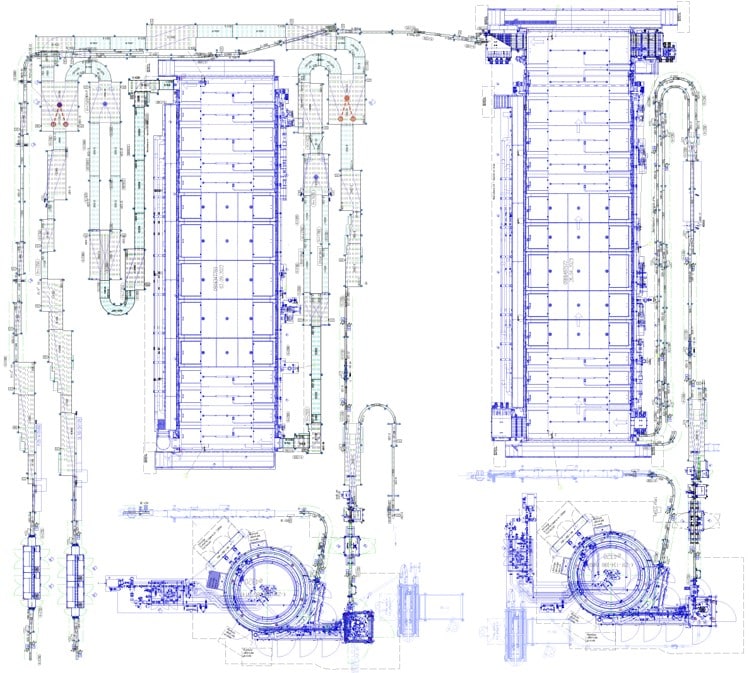

From mass flow to single-lane conveyor

With the LinaFlex eSync, there is no longer mass flow conveyance throughout the entire line. The buffer spaces are inside the pasteuriser.

The new infeed module

The change from single-lane into mass-flow conveyance is done within the infeed module of the LinaFlex eSync - the result is an electronic block with the filler.

How does the infeed module work?

Thanks to the variable speed control system, the pasteuriser's infeed module adapts to the output of the filler.

- The entire content of the filler carousel fits into the infeed module.

- When necessary, the transfer of cans into the pasteuriser is delayed.

- It forms a straight and compact row of cans for the infeed and discharge or if the filler is operating with reduced output.

- A new infeed configuration makes a more gentle treatment possible and lowers the pressure on the cans from 15.5 kilograms to 6 kilograms.

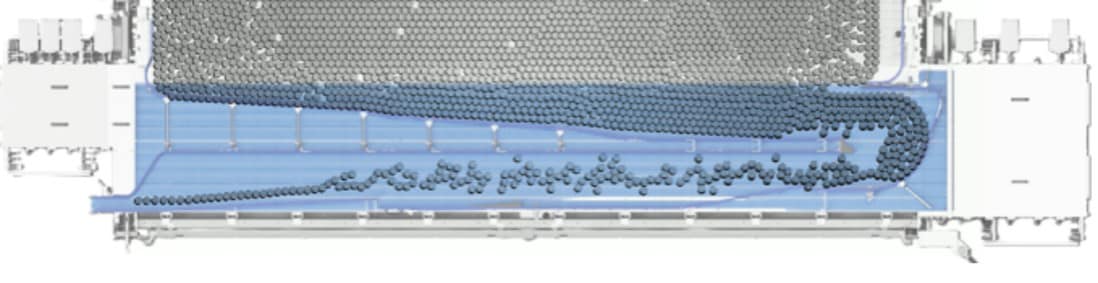

The buffer spaces in the pasteuriser

The integration of the downstream buffer in the pasteuriser makes a larger buffer volume possible while requiring less space. There is also no need for mass flow conveyors due to this. The result: the line layout is changed significantly.

Benefits to you

- Few interfaces between the machines

- Faster commissioning and shorter change-over times

- Improved access for operation and maintenance

- Saves space: Up to 40 percent in the wet section, around 25 percent in the entire line

- Higher output possible with the amount of same space

The integrated buffer is available in three sizes and allows for up to 8 minutes of buffer time.

Using savings potentials

Energy savings

- Dynamic adjustment: Proximity sensors at the infeed conveyor detect the number of cans and flexibly adjust the speed to the filler (25-100%).

- Energy efficiency with partial load: The recuperation zone is optimally used at low speeds.

- Early pasteurisation: The heat recovery starts from the back and goes through the zones to the front. With early pasteurisation, quick speed changes are possible without interruption.

- Cascading approach: During slow production, the recuperation zone is expanded - an intelligent approach with partial load instead of efficiency loss.

- Consistent product quality: No microstops, no over-pasteurisation - the result is a smooth process and a higher quality of product.

- The use of low-pressure nozzles reduces the amount of energy required by up to 45 percent.

- An integrated thermal insulation significantly reduces heat loss.

- Internal recuperation efficiently recover both heat and cooling energy.

- By using sustainable sources to produce electricity and warm water or steam, the pasteuriser can be CO2 neutral

- The optional use of heat pumps additionally increases the electrification rate and gets the most energy out of the products.

Benefits to you

Better container conveyance

The single-lane connection makes block synchronisation with the filler possible. Thanks to Speed Control, the LinaFlex eSync matches the speed of the filler and gently handles the containers. Speed Control and Recu+ get the most out of recuperation.

Slimmer line layouts

The single-lane connection of upstream and downstream machines allows for a flexible design in the line layout. With this, up to 40 percent of the space in the wet section can be saved. This means more room for planning and better accessibility to operator areas.

More buffer in a smaller area

By integrating the line buffer into the LinaFlex eSync, more buffer can be achieved in a smaller space. Combined with the Speed Control function in the new infeed, the line can stay in operation longer, which allows for a large amount of energy to be saved.

More automation, less complexity

By blocking the LinaFlex eSync with the filler, the line's complexity is greatly reduced. Fewer operation interventions are needed this way.