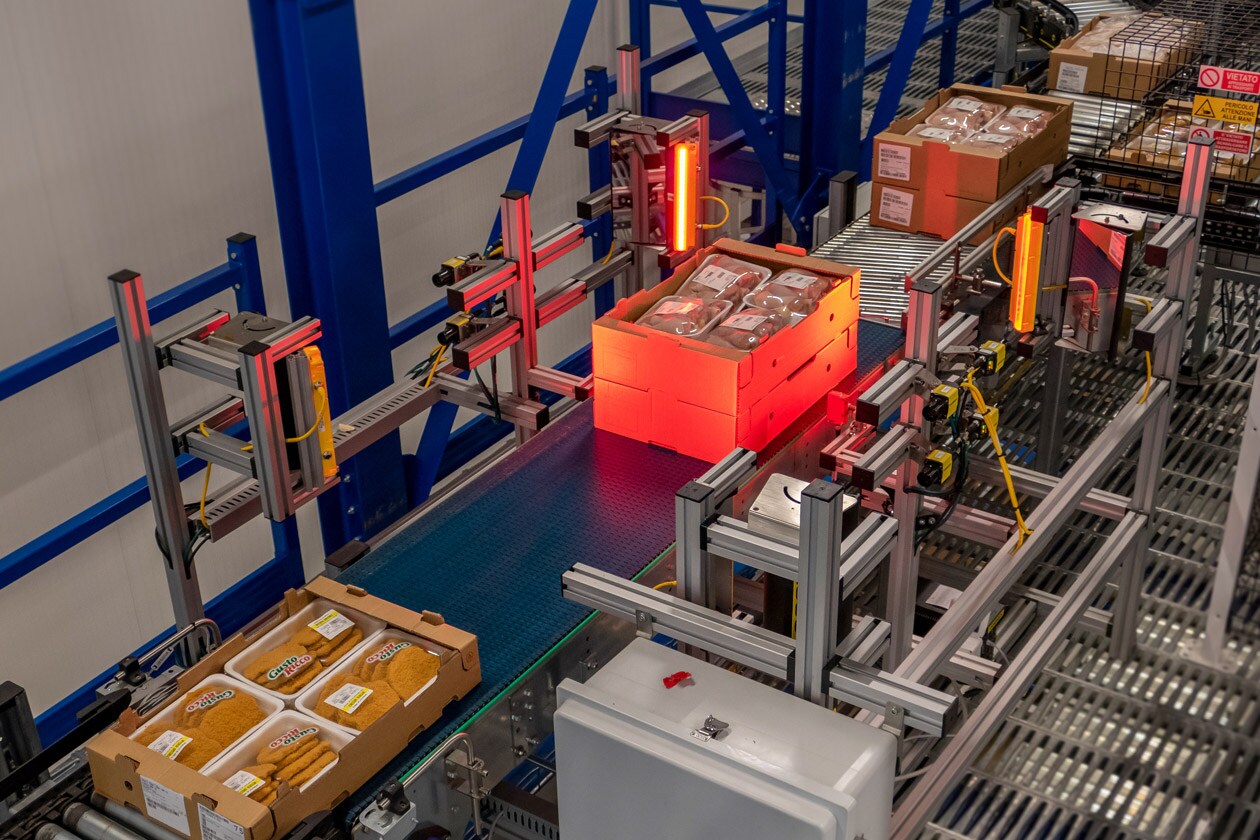

The intralogistics and material handling specialist System Logistics has been part of the Krones Group since 2016. While Krones operates primarily in the beverage and liquid-food sectors, System Logistics’ clients include companies in the grocery business and other industries, each of which has its own very specific requirements when it comes to logistics. For fresh, refrigerated products, maintaining a continuous cold chain across the entire logistics process stands at the very top of that list.

Another particular challenge that is unique to the transport of fresh foods relates to pack shape: While beverage containers always come neatly packaged in stackable, easy-to-handle units such as six-packs or crates, fresh items like meats are simply loosely placed in crates or boxes. The advantage of this method is that it makes for quick unpacking and stocking into refrigerated display cases at the supermarket. However, it also presents a real logistical challenge. Since these cases are usually open at the top and product might stick out, depending on the size and shape of the contents, they may not always be easily stackable.