Reduced-sugar jams, preservative-free soups, plant-based milk alternatives: Healthy, sustainable nutrition is trending right now. The majority of people in the European Union self-report that they eat a mostly healthy, sustainable diet, focusing especially on avoiding sugar, flavor enhancers, artificial flavorings, fats, and preservatives.

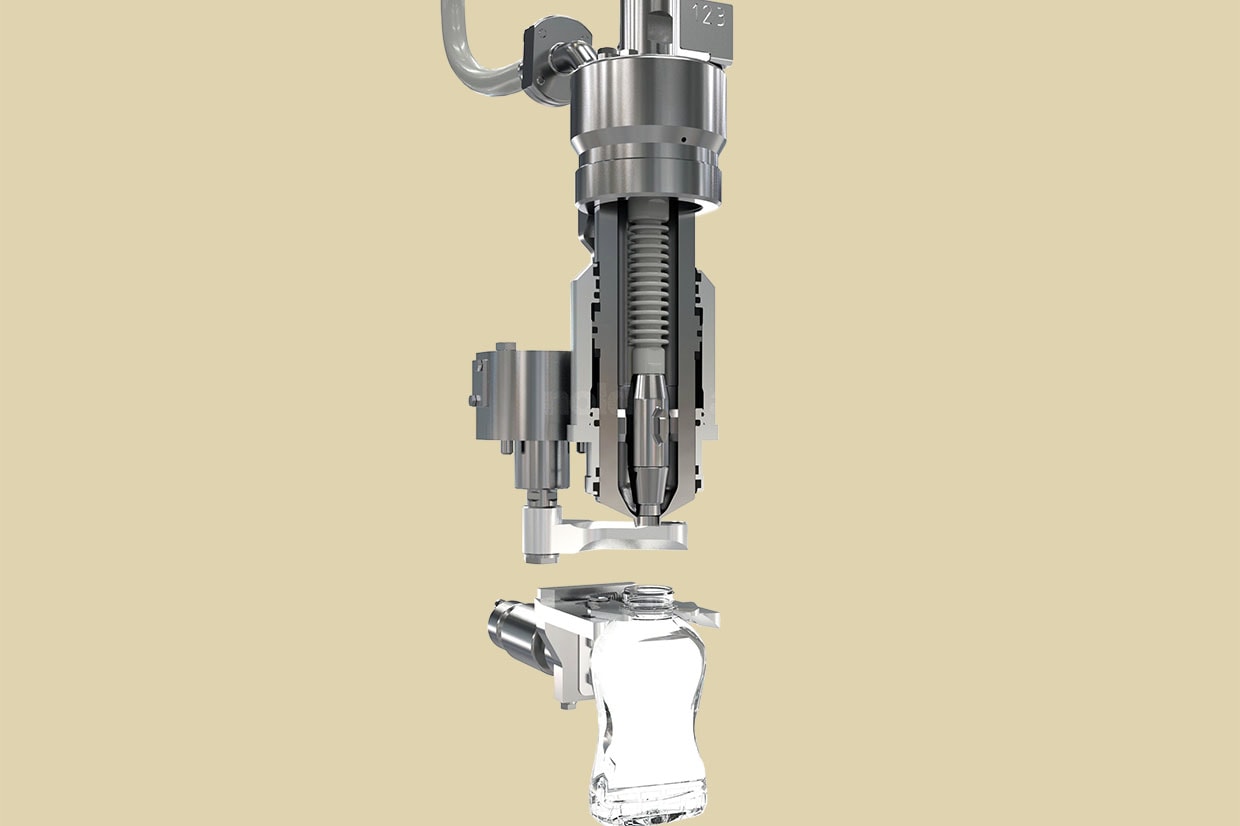

For producers, that means a new set of hygiene requirements for filling liquid food and for the manufacture and handling of containers. Clean and efficient processes are essential, as is low energy consumption. As a system supplier, Krones has already made all of this a priority and offers the right process, plastics, and filling technologies. Krones’ expertise in filling water, juices, and beer transfers well to sauces, soups, mustards, and ketchup – with modifications made to account for the higher viscosity of these liquid foods.

Our goal is to offer our customers flexible, environmentally friendly solutions that are tailored to their needs.

Josef DeglmannHead of Sales Home and Personal Care, Food

Josef DeglmannHead of Sales Home and Personal Care, Food