When you think of France, and Burgundy in particular, you’ll likely think of wine, not beer. But now Beaune, the capital of the wine-growing region of Burgundy, is also home to the newly established Brasserie de France. Because a beer-maker can benefit just as well from the region’s savoir vivre and existing logistics infrastructure, such as local suppliers of bottles and packaging.

Brasserie de France has been producing its own beer for just under a year now. When it came to planning the production and filling line, the young company put its trust in Kosme. The startup brewery and the expert for smaller-scale filling lines are a perfect match.

Brasserie de France is a unique sort of brewery: It doesn’t just produce beer. It also offers brewing and tasting workshops, runs a research center for fermentation processes, and trains young apprentice brewers. It’s what you might call a brewing campus rather than simply a brewery. And ultimately, Brasserie de France wants to revive the craft of brewing in France, make it once again attractive and financially viable, and lead it into the future.

The enterprise began operations in August 2022. Its establishment also has a unique story. When they started the company, co-founders Jean-Claude Balès and Anthony Verdureau knew nothing at all about brewing. Both had a background in digital technologies and had already launched several tech companies.

What they lacked in brewing expertise, they made up for with a healthy dose of entrepreneurial spirit. And that is precisely what they would like to pass on to others. They are champions of socially responsible business practices that are rooted in ethical values, social justice and respect for the environment. Their manifesto reads: “For us, positive entrepreneurship is a lever for sustainable economic performance, environmental innovation, social emancipation and professional integration.” As a result, the campus brings together people of diverse backgrounds, including foodies, microbrewery founders, beer enthusiasts and people who simply want to make a fresh start by training in the field.

A special kind of partnership

Anyone entering the brewery business for the first time with no prior knowledge about brewing beer will need a strong partner at their side. Jean-Claude Balès and Anthony Verdureau found that partner in Kosme, the italian part of Krones specialized in Compact Class. What makes this partnership special is that Brasserie de France entrusted Kosme with all of the planning and commissioning of its production and filling line. This was the first time the experts at Kosme would build an entire, greenfield production plant.

An initial meeting between the two partners took place in August 2021, just one year before the brewery began operations. Various aspects were especially important to Brasserie de France. First, the new line would need to be highly flexible with respect to capacity, container formats and beverage types. That’s because it would not only be filling beer but, in the future, also carbonated soft drinks, and it would have to be able to handle various-sized glass bottles and beverage cans. Second, because the brewery has a small number of employees, production and filling would need to be automated as much as possible. Third, careful scheduling was crucial since the company wanted to be ready to launch operations in just a year’s time. Fourth, it was essential to stay not only on schedule but also on budget. “In particular, it was important that we have a partner at our side who could provide support and advice not only in the startup phase but also for the long term,” emphasizes managing director Anthony Verdureau.

In particular, it was important to us that we have a partner at our side who could provide support and advice not only in the startup phase but also for the long term. Anthony VerdureauManaging director

One line – one point of contact

Kosme met all the requirements. “Thanks to our technical expertise, we were able to optimally advise the customer and put together a line that met the technical specifications and stayed within the timeframe and budget,” says a gratified Enrico Perin, expert for systems engineering and process technology at Kosme, who was in charge of planning the line. “Designing the line was an intensive process. Every day we learned what it means to produce and package consistently high-quality beer,” says Anthony Verdureau.

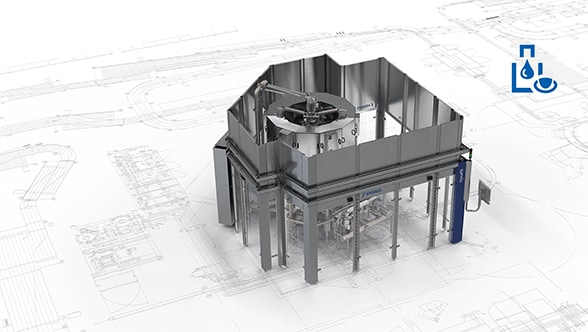

The filling line comprises machines from Kosme as well as other certified suppliers. For example, it features the semi-automated Semidepal depalletizer, the Barifill Canto multipurpose filler, a fill level inspector, a container dryer and a Sensicol Linear labeler. For the beer production itself, the line primarily uses machines from one technology partner. “For Brasserie de France, the fact that all of the machines come from a single source was and remains a decisive factor,” stresses Enrico Perin. It means one person is responsible for keeping an eye on the schedule and budget and ensuring that they are met. “We also play an important role as intermediary since we essentially translate the technical specifications to the other vendors,” explains Enrico Perin.

One for all: Design and installation, training and service

In June 2022, Kosme delivered the machines to the brand-new 2,500-square-meter production hall and installed the entire line in two months’ time. Kosme then fulfilled another of the startup’s essential requests: training for brewmaster and production manager Paul Venot. “Here, too, it was important that we have a single point of contact so the production manager wouldn’t have to communicate with multiple different vendors,” explains Leonardo Formentin, project manager for after-sales service at Kosme. And after commissioning, too, Kosme serves as the single entity responsible for service and maintenance and for ensuring that any needed spare parts are delivered quickly.

Since its founding, Brasserie de France has been filling its beer into three different container formats: 0.35- and 0.75-liter glass bottles and 0.35- and 0,5-liter cans. But the filling line offers the flexibility to accommodate additional formats as well. This year, Brasserie de France will produce around 12,000 hectoliters of beer: 23 different beers under six different brands. Besides their flavors, the beers are memorable for their creative labels and funny names like “Soif de toi” (“Thirsty for you”). The company plans to add more beer brands and carbonated soft drinks to its portfolio soon. In particular, Brasserie de France intends to promote entrepreneurship on all aspects of brewing culture. And perhaps the Burgundy region will one day be famous not only for its wines but also for its beers.