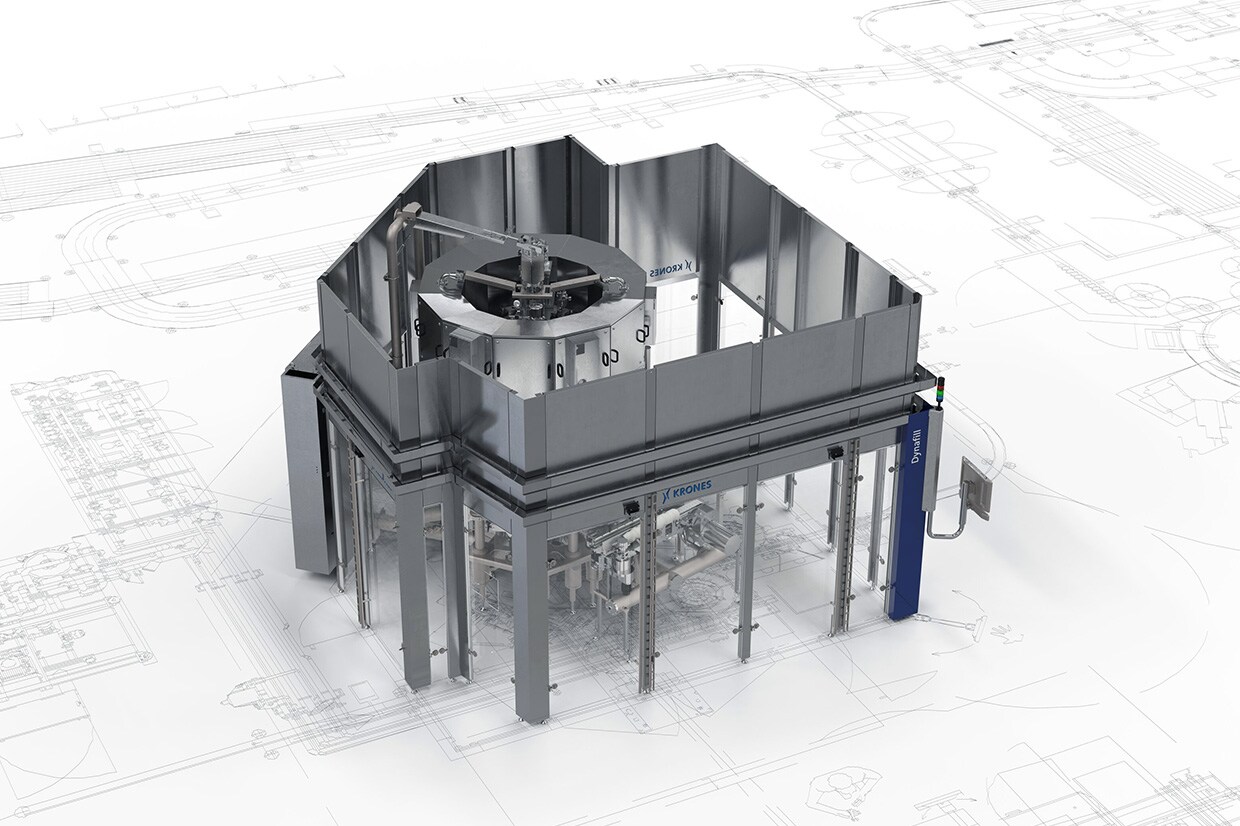

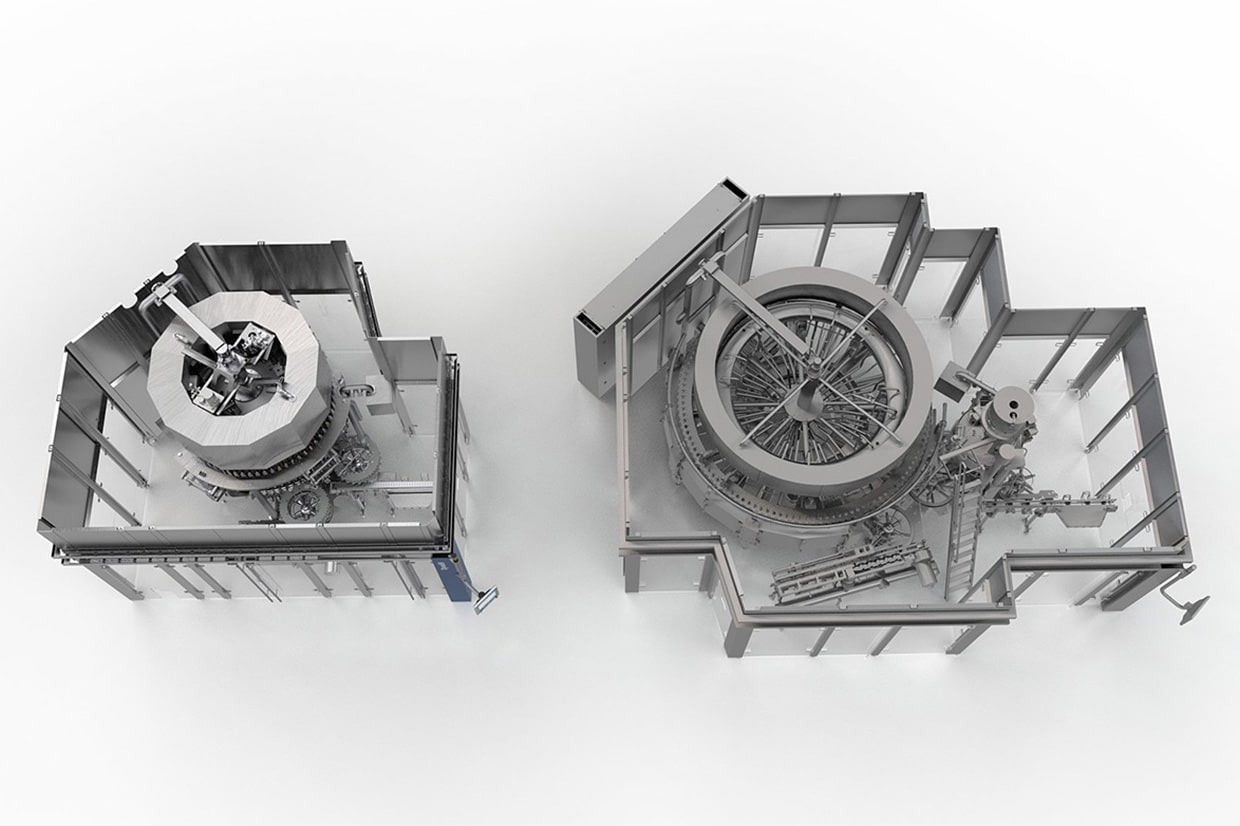

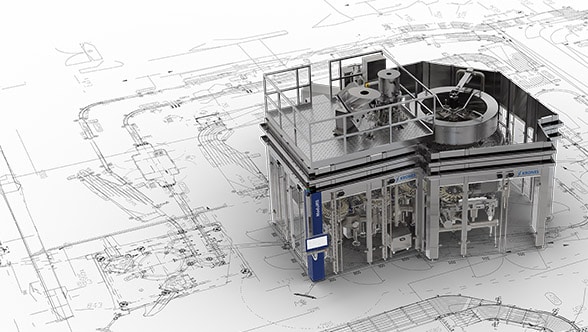

One of the vital issues for any forward-looking brewery is this: How can I save energy throughout the production process, in order to put it on a more sustainable footing? Steinecker’s answer to this question is called Brewnomic. This concept developed by the Krones subsidiary enables a brewery to be energy-self-sufficient by smartly using and recovering the residual materials from the brewing and filling processes. Brewnomic consists of several modules, many of which relate to the brewing process. But systems and lines used in the bottling operation can also contribute to overall sustainability. The Dynafill, which combines filling and crowning on a single functional unit, fits in neatly here – for a number of reasons which in combination offer a whole series of rewarding benefits.