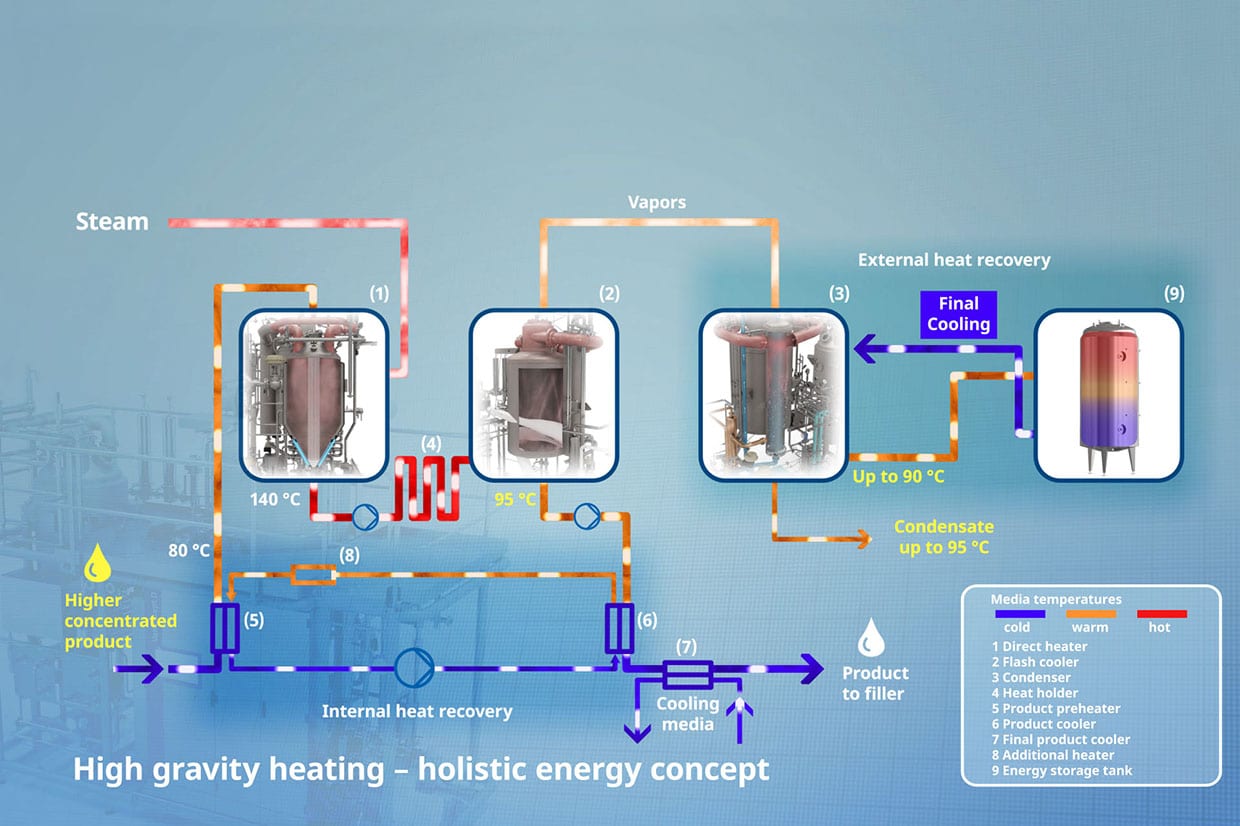

Choosing a suitable process for product heating is not always easy. Preference is often given to indirect heating because it entails a smaller initial investment and allows for energy recovery. However, heating the product, keeping it hot and then cooling it down again takes far longer – and the resulting thermal stress can affect the product and its taste.

The gentler alternative is direct heating, which is particularly well suited for highly sensitive products like plant-based milk alternatives and milk-based drinks. That’s because the entire process of heating up and cooling down the product takes only a few seconds. So, it’s certainly gentle on products. But it isn’t exactly energy efficient, because it takes quite a lot of energy to bring a product up from 80 to 140 degrees Celsius in a matter of mere seconds. Now, Krones has addressed this shortcoming – and successfully at that.