Flectra: A labeller for diverse industry needs

- Krones is reorganising its “machines and lines for the low and medium output range” business.

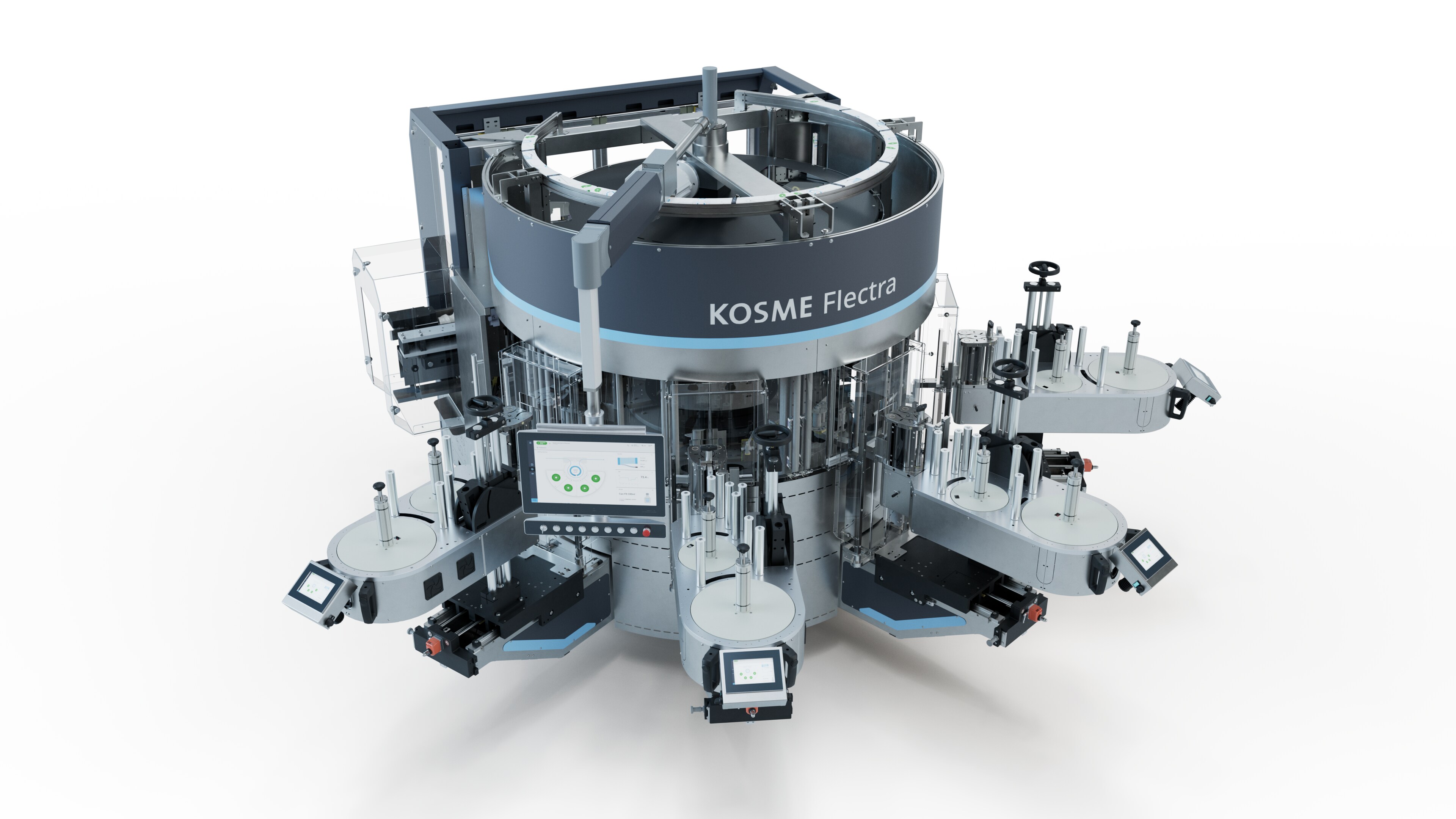

- Flectra: A new generation of labellers is the result of the first joint development project between Kosme and Gernep.

- The labeller is designed for the low and medium output range and scores points with its high degree of flexibility, simple changeovers and optimised cleaning options.

- Flectra can be used in the food and beverage industry as well as the home and personal-care and pharmaceuticals sectors.

In light of the current transformation in the beverage and liquid-food industry as well as rising demands for sustainable, competitive and efficient products, Krones is restructuring its profitable and growing Compact Class line of business. It is here that Krones brings together its solutions for filling and packaging consumer goods in the low and medium output range. Compact Class is made up of four different subsidiaries: KOSME Italy, KOSME Austria, the sales and service company KOSME FBA and the labelling-machinery specialist Gernep. In future, these units are to be combined into one. The first step in that direction was a joint development project between KOSME and Gernep, which culminated in a new generation of labelling machines.

State-of-the-art technology, maximum flexibility

The new labeller, which has been given the name Flectra, uniquely integrates the two companies’ combined expertise in labelling – more than 80 years’ worth. Designed for the low and medium output range, it can handle a diverse array of industry requirements in the beverage and liquid-food industry as well as the home and personal-care and pharmaceuticals sectors.

These different applications require an exceptional degree of flexibility, which is why Flectra is available in two machine designs: pre-modular and fully modular. On the fully modular machine, the labelling stations can be flexibly switched out by means of a trolley. Thanks to plug-and-play func-tionality, the main parameters are set automatically, for fast and easy labelling-station change-overs. Customers also benefit from improved self-adhesive and cold-glue label applicators. The latter were developed in close collaboration with the Krones Group. An oil-circulating lubrication system and polygon shafts for more precise labelling are integrated as standard. The labelling station housing is now more accessible, making for easier handling parts change overs and optimised cleaning options.

The Unigrip multifunctional clamping starwheel can also be integrated for added flexibility. It handles round containers with different diameters and is height adjustable, which minimises changeovers and production interruptions. Moreover, to ensure a perfect finished product, the monitoring systems for optical alignment and label inspection have been completely revamped to feature maximum precision, a smaller footprint and shorter distances for bottle alignment. All of that makes Flectra more compact, highly flexible for handling a variety of containers, and less complex.

Digital solutions enhance user-friendliness

In today’s machinery manufacture, hardware is as important as ever. But digital solutions make all the difference when it comes to improving user-friendliness. Flectra has a new, flat and more powerful control panel (HMI) with a fully reconfigured and intuitive user interface. The 270°-swivel arm allows operators to control the labeller from nearly all sides. The system can also be integrated into the Krones Operation Platform (KOP), a digital ecosystem that ensures uniform line monitoring and the evaluation of specific machine data.

The prototype of the Flectra will be on display at the drinktec, with four self-adhesive-label applicators, integrated monitoring systems and the new human-machine interface (HMI). The first reference machines for self-adhesive and cold-glue labelling will be installed at customer plants at the start of next year.

Download

Dr. Anne-Kathrin Bräu

Peter Mörtl