Single-lane instead of bulk conveyors: Krones’ fresh approach to pasteurisation

- With the LinaFlex eSync, Krones has reinvented the layout for canning lines

- Single-lane instead of wide bulk conveyors throughout

- A line buffer integrated into the pasteuriser cuts the amount of floor space needed in the wet end by up to 40 per cent

- Lower back-up pressure reduces the risk of sensitive cans being dented and/or scratched

- Heat recovery, speed control and optional heat pump make for significantly lower energy consumption

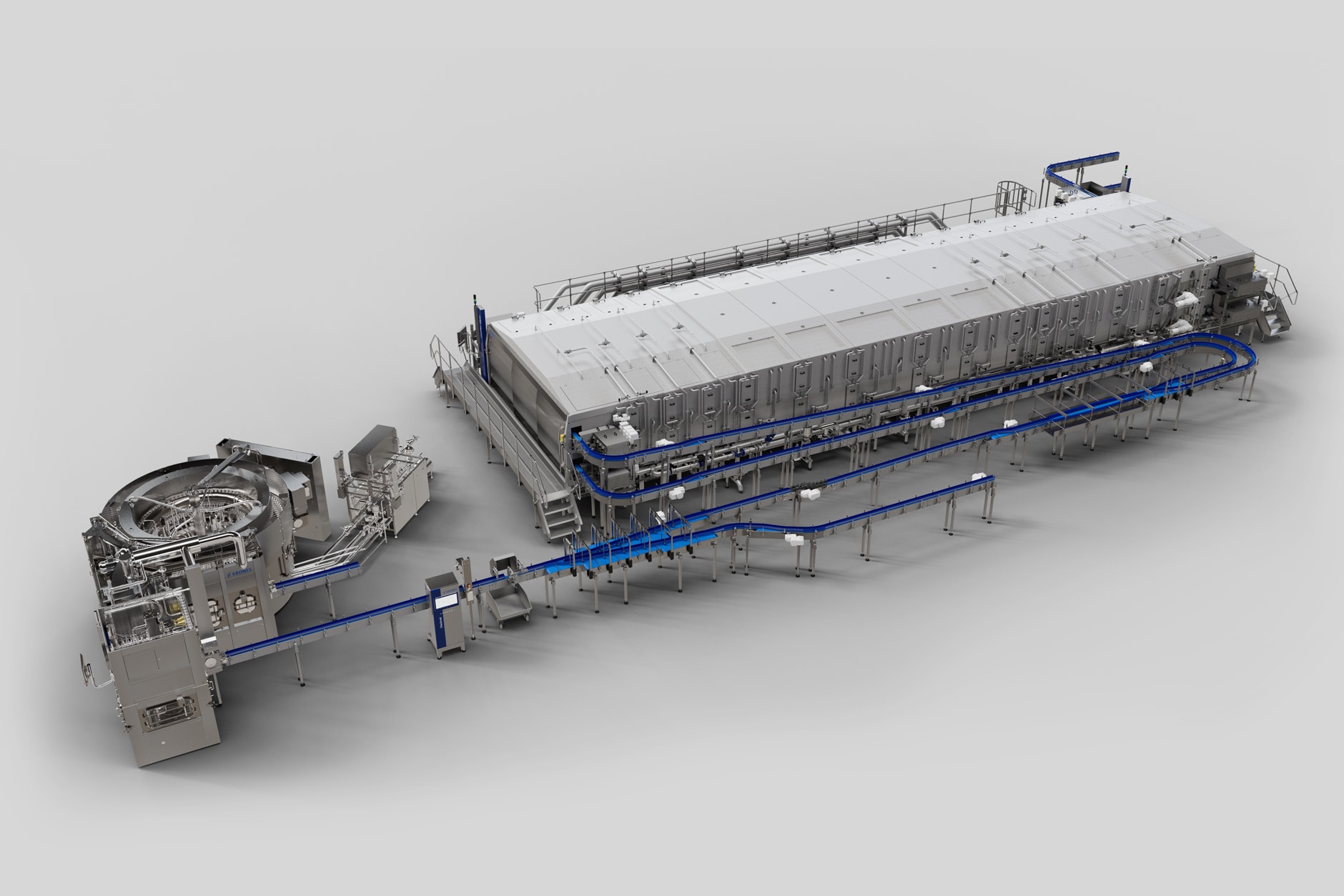

Krones has put a pioneering pasteurisation solution on the market in the shape of its new LinaFlex eSync. For the first time, the system combines a fully integrated dynamic line buffer with single-lane transport throughout the line, thus setting new standards in beverage filling.

Instead of wide bulk conveyors with external buffering sections, the LinaFlex eSync features a swift, slimline conveyor system. Thanks to a compact yet efficient line layout, the cans travel in a closed-packed flow from the filler to the pasteuriser and then to the packer – no interim buffering needed. Not only does that substantially reduce the amount of floor space required (by up to 40 per cent in the wet end and by up to 25 per cent in the entire line), it also makes it easier to access the machines for maintenance and operation.

Buffer management integrated into the pasteuriser

Buffer management has been fully integrated into the pasteuriser. A separate variable-speed buffer belt creates a dynamic buffer section, whose capacity can be flexibly matched to the current line speed. “The transitions between the different belt speeds are technically ingenious,” explains product manager Niels Clausen. “In this way, the system can respond to any fluctuations in production – both upstream and downstream of the pasteuriser – with the requisite flexibility.”

Yet another advantage: Gentle can handling reduces the risk of mechanical damage. That makes it possible to use lighter cans with thinner walls, which saves material and raises sustainability levels. And thanks to the compact design, significantly better use can be made of the space available in the production line.

Heat recovery and speed control boost energy efficiency

The LinaFlex eSync scores just as highly when it comes to energy efficiency. Thanks to a proven heat recovery system between the heat-up and cooling zones, the amount of energy needed is substantially reduced. Functions like speed control, zone insulation, low-pressure-optimised nozzles and an optional cooling module with heat pump complement the system perfectly. The latter enables the heat recovered in product cooling to be used to heat the pasteurising zones or to be fed into a central heating grid. The module can achieve a COP (coefficient of performance) value of up to 2.9.

On the shopfloor at DICO Drinks

The pasteuriser’s prototype has been up and running at DICO Drinks in Hückelhoven, Germany, since July 2023. Rated at 95,000 containers per hour, the system provides a buffering capacity of three minutes on just six square metres. Sven Breitfeld, the Head of Production, is impressed: “The footprint difference is striking – the new system is a genuine gain in efficiency.”

About Krones

The technology company Krones headquartered in Neutraubling, Germany, is a global leader in developing and manufacturing state-of-the-art machines and complete lines for the fields of process, filling and packaging technology. Its portfolio is perfectly complemented by additional products and services provided by the Krones subsidiaries, such as solutions for anything to do with digital transformation, intralogistics and plastics recycling. Krones employs more than 20,000 people worldwide. Consolidated sales in 2024 totalled 5.3 billion euros. The Krones Group includes not only Krones AG (listed on the stock exchange), but also more than 100 subsidiaries and further production, sales and service companies worldwide.

Download

Dr. Anne-Kathrin Bräu

Peter Mörtl