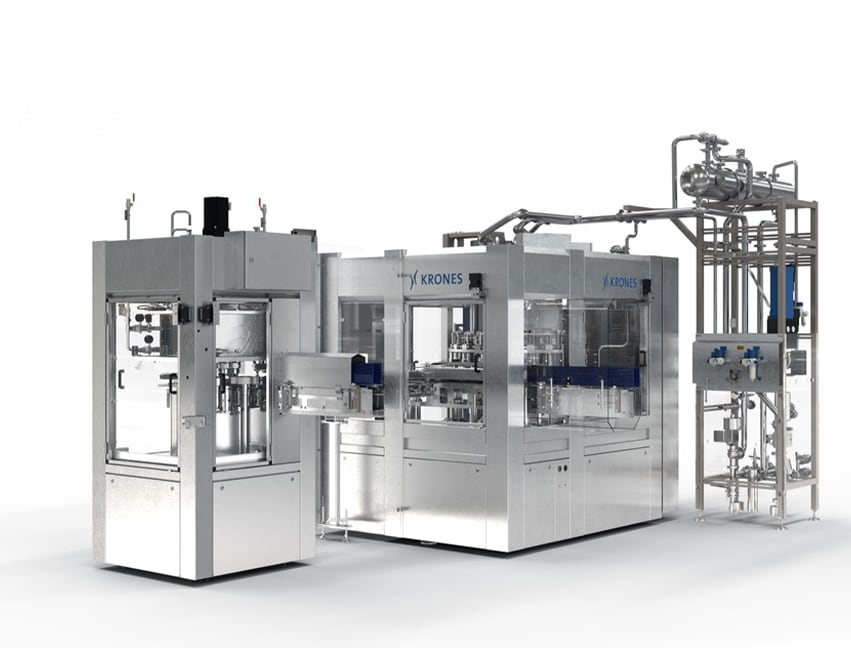

The can filler for the low output range

Technology from large breweries for craft brewers

When it comes to filling craft beer into cans, the Craftmate C is your ideal partner. The Krones can filler is an expert for the low output range. It safely cans even small production quantities starting from 12,000 containers per hour* and it offers double flexibility: This all-rounder processes cans of various sizes and formats, and masters not only beer, but also carbonated beverages and wine.

At a glance

- Fills beer, carbonated soft drinks and wine in cans

- High flexibility also in the low output range

- Cost-efficient filling technology in the quality you are used to from Krones

- High filling quality with guarantee values comparable with high-performance machines

- Short change-over times for different can sizes

- Compact design

* Based on a content of 16 oz

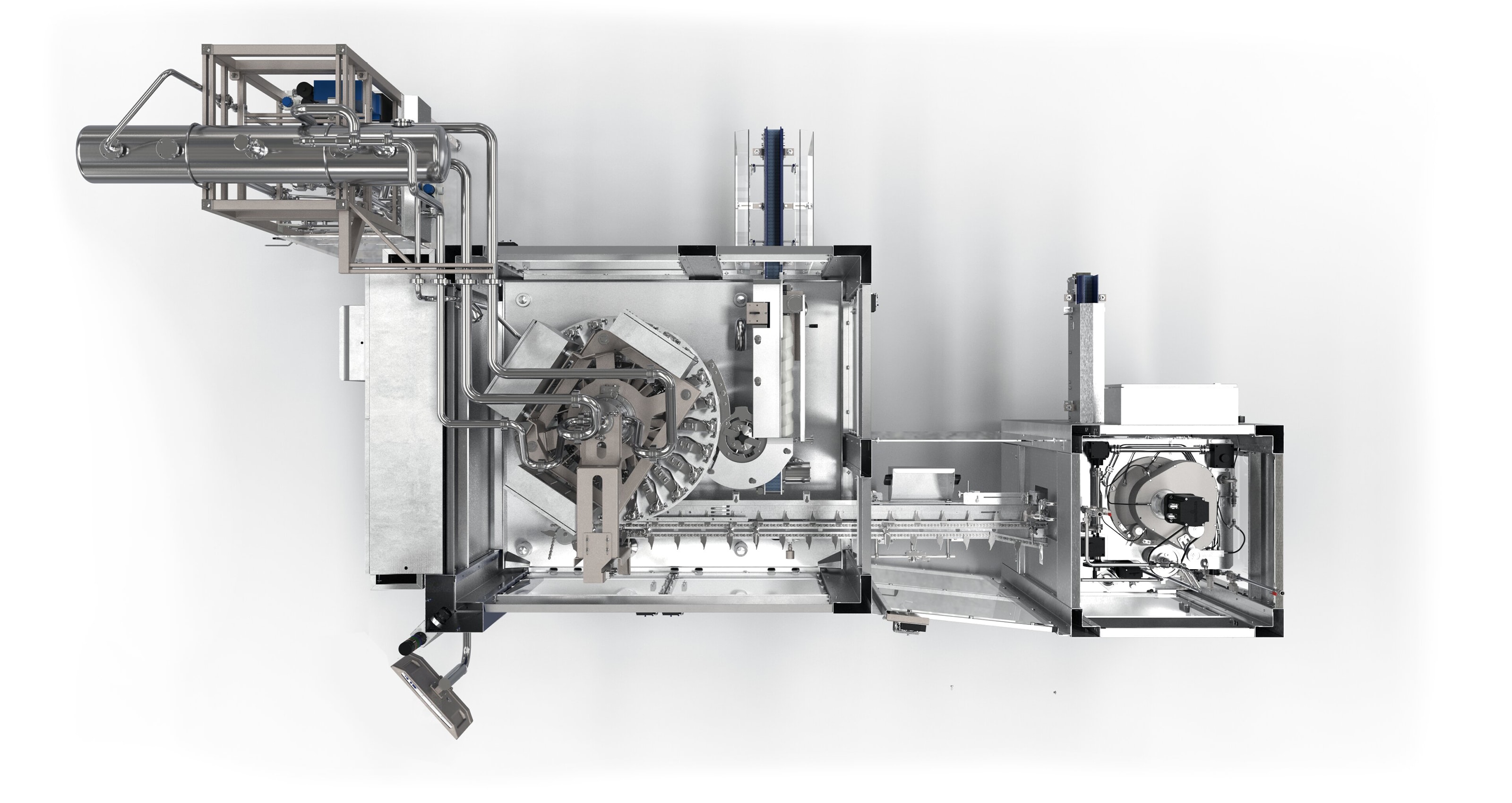

The components

Details

| Diameter |

1,080 mm |

| Number of the filling valves | 24 |

| Pitch diameter | 141 mm |

| Products | beer, carbonated soft drinks and wine |

| Can formats | Standard format: 211/202, Optional: 204/202 to 300/209 |

| Product temperature | 2 °C to 16 °C |

| CO2-content | 3,8 g/l to 6,0 g/l |

| Filling system | Volumetric filler with inductive flow meter |

| Valve manifold | Manual version (Krones standard) with product tank installed on top for the least possible product loss |

| CIP cups | Manual insertion of CIP cups |

| CIP | Closed CIP circuit |

| Height adjustment system | Manual |

| Machine type | Tabletec table top (stainless steel) in inclined design for draining of cleaning agents |

| Design basis | Compact machine for easy transportation (sea freight) |

| Controller | Siemens S7 oder Allen Bradley |

| Drive | servo drive system |

| Filler-capper block synchronisation | Servo motor connection of the can seamer |

| Seamer | 4 seaming heads |

Technical details

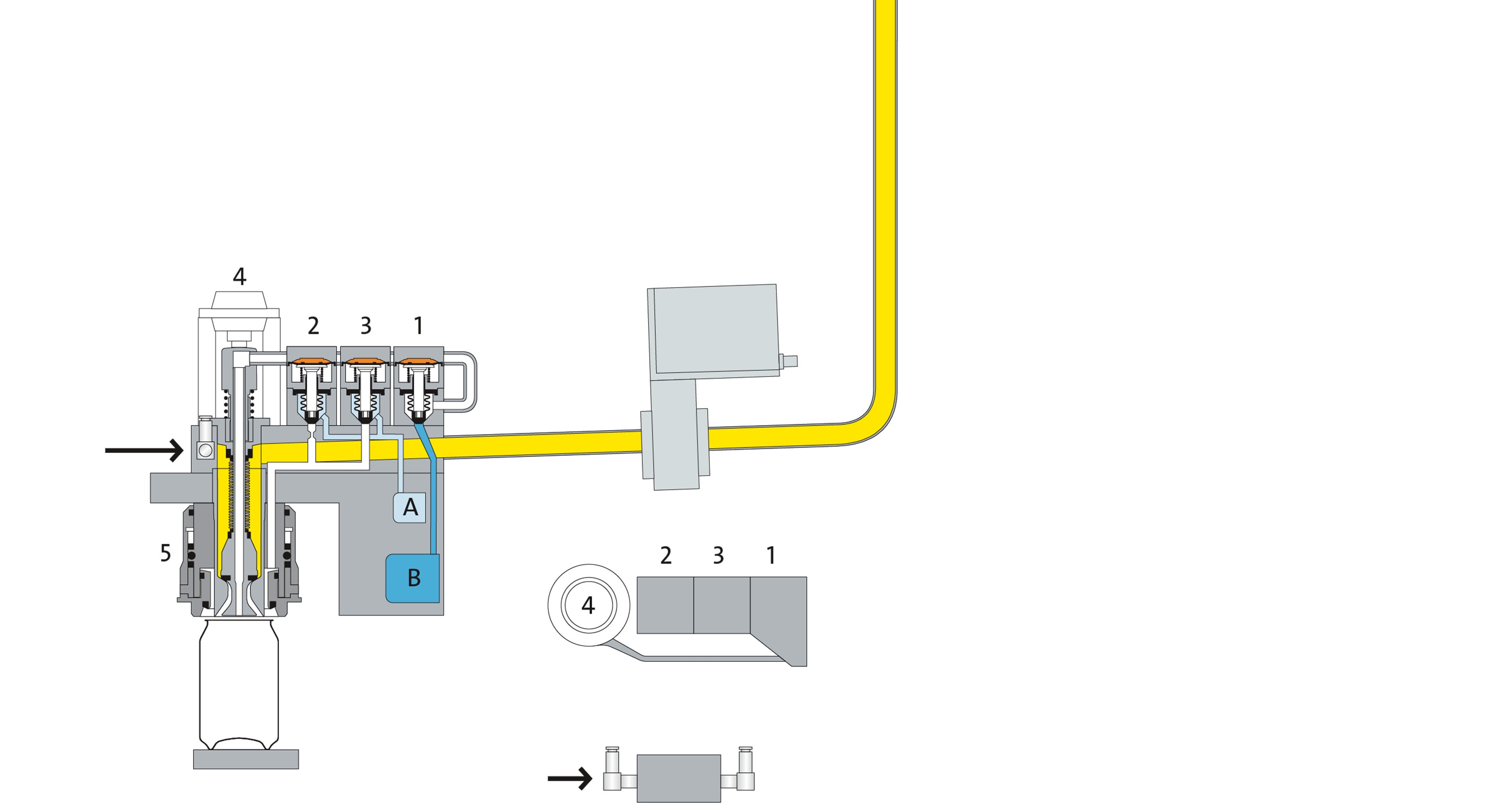

- Filling valve with pneumatically controlled centring bell without lifting cam

- Cylinder with Teflon bellows for controlling the process gas

- Inductive flow meter for fill quantity determination

- Product tank at the valve manifold for product supply

Benefits to you

Double flexibility

The Craftmate C is your specialist for can filling in the low output range and is also extremely versatile: It fills beer, carbonated beverages and wine in a range of can shapes and sizes.

Innovative technology

The electropneumatically-controlled filling valves work very reliably and thanks to the inductive flow meter, the fill quantity can be determined up to the point. Pressing-on and pressurisation of the cans is performed via a double-acting cylinder and a differential pressure chamber.

Easy to clean

An inclined table top and manually inserted CIP cups ensure easy machine cleaning.

Compact design

The product is fed to the machine via laterally-positioned buffer tanks and the valve manifold and control cabinet are right next to the filler. This way, the Craftmate C requires just a minimum of space in the bottling hall.

Low transport costs

Of course, these compact dimensions have plus factors when it comes to the transport: Since the entire machine can be placed in one sea freight container, the costs for shipment are accordingly low.