If more is produced compared with the previous year, the quantity of material that has to be transported from one place to another naturally also rises. That this doesn’t necessarily mean an increase in the number of shipments as well has recently been demonstrated by the Krones plant in Debrecen, Hungary: Although the production volume grew by a healthy 31 percent last year, the number of trucks used rose by only six percent.

The Krones plant in Hungary has managed to increase its production output without the number of trucks used rising to the same extent. How did it manage that?

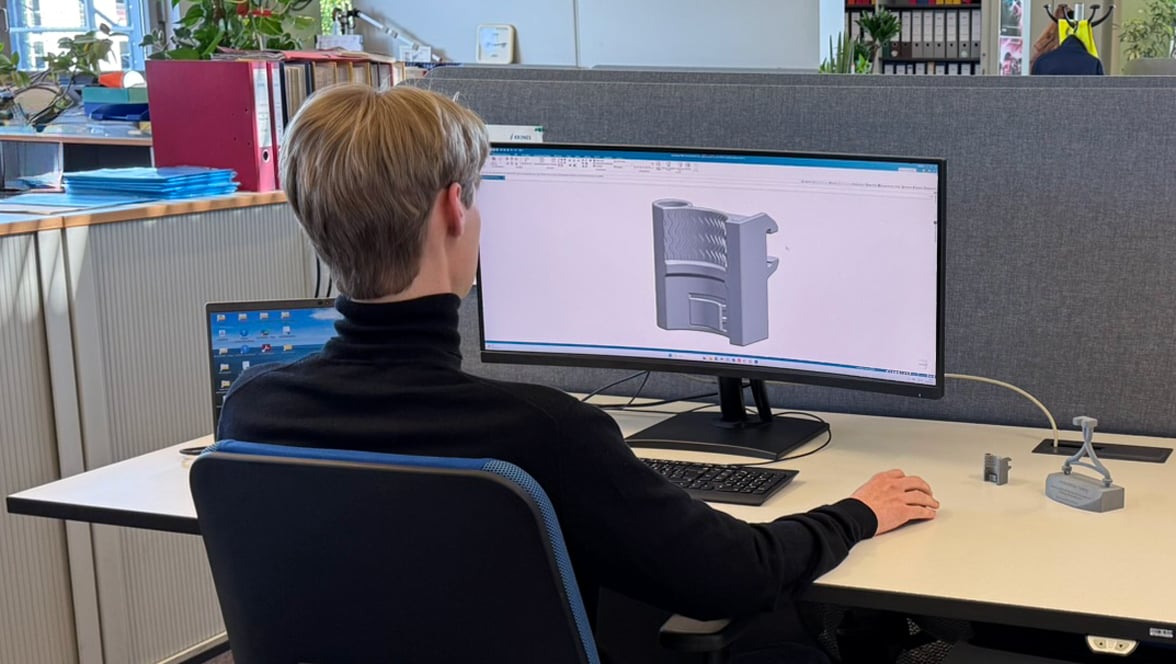

This success can be attributed to an increase in the packing density. The experts at Krones Hungary analysed in advance how many kilograms of transported goods can be carried on a pallet at the moment – and they spotted some potential for optimisation. By loading the pallets with as much material as possible, the stowage space in the truck can be used more efficiently. A specially developed transport frame also makes it possible to accommodate the goods double-stacked in the truck, making even better use of the available stowage space. The outcome is that 25 percent of truck journeys were saved – which is equivalent to a massive 844 vehicles, each of which would have had to cover a distance of at least 1,800 kilometres.

But that's not all: The journeys between the plant in Debrecen and its customers are constantly being analysed for further potential optimisation with the aim of finding transport options that release the fewest emissions. In the past the goods were shipped from the Hungarian plant to the main site in Neutraubling, where they were then packed and sent on to the customers. Since this procedure not only takes extra time but also causes unnecessary emissions, however, goods for overseas now travel directly from the plant in Hungary straight to the customers via the ports of Hamburg and Bremerhaven.

Cutting emissions the top priority

This both enables a reduction in transport at the main site in Neutraubling and saves time. The shorter transport routes also mean lower emissions. Only European shipments are currently still being handled through Neutraubling, but the long-term aim is to switch to direct shipping without intermediate storage for these too. As soon as the construction of a rail network and a new loading terminal in Debrecen allows goods to be transported by rail, this possibility will be evaluated accordingly.