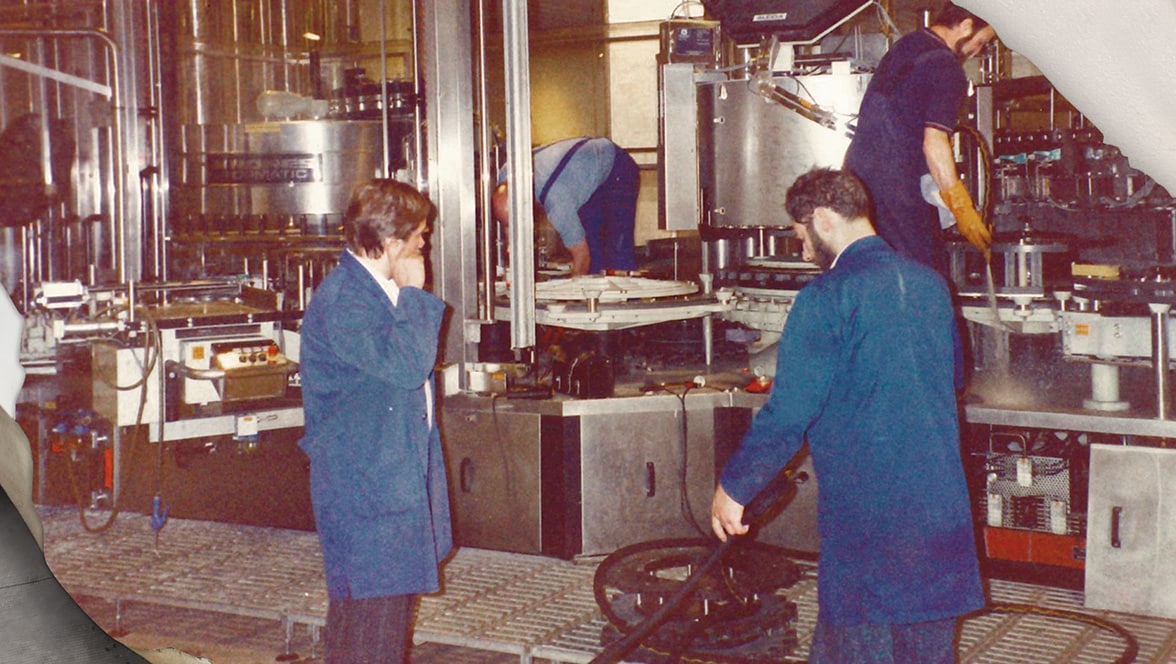

Machines whirring, bottles clinking, hissing noises: These are the sounds you hear in buildings where Krones machines go tirelessly about their work filling beverages. If even one single component fails to do its bit, though, under certain circumstances this can bring the whole line – and the whole plant – to a standstill. It can prove difficult to find the right spare parts, particularly if the machines are old. Fortunately, Krones recognised this problem at an early stage and set up a dedicated team that is specially equipped for such cases: Obsolescence Management.

Reactive, proactive, strategic – the three ways to get spare parts

Components are called “obsolete” if, for instance, they are ageing, no longer fit for purpose or not needed any more. In practice, this can take many different forms: Components are no longer manufactured, operating systems stop receiving updates or new legislative standards make modernisation essential. Even knowledge can become obsolete. This happens when colleagues retire and the machines can no longer be maintained as they were before, making it impossible to apply certain production methods.

Not least, the requirements from customers also change constantly – and the market adapts. That’s why it is important, particularly for a technology group like Krones, to develop strategies against obsolescence at an early stage in order to ensure the customary commitment to a smooth Lifecycle Service.