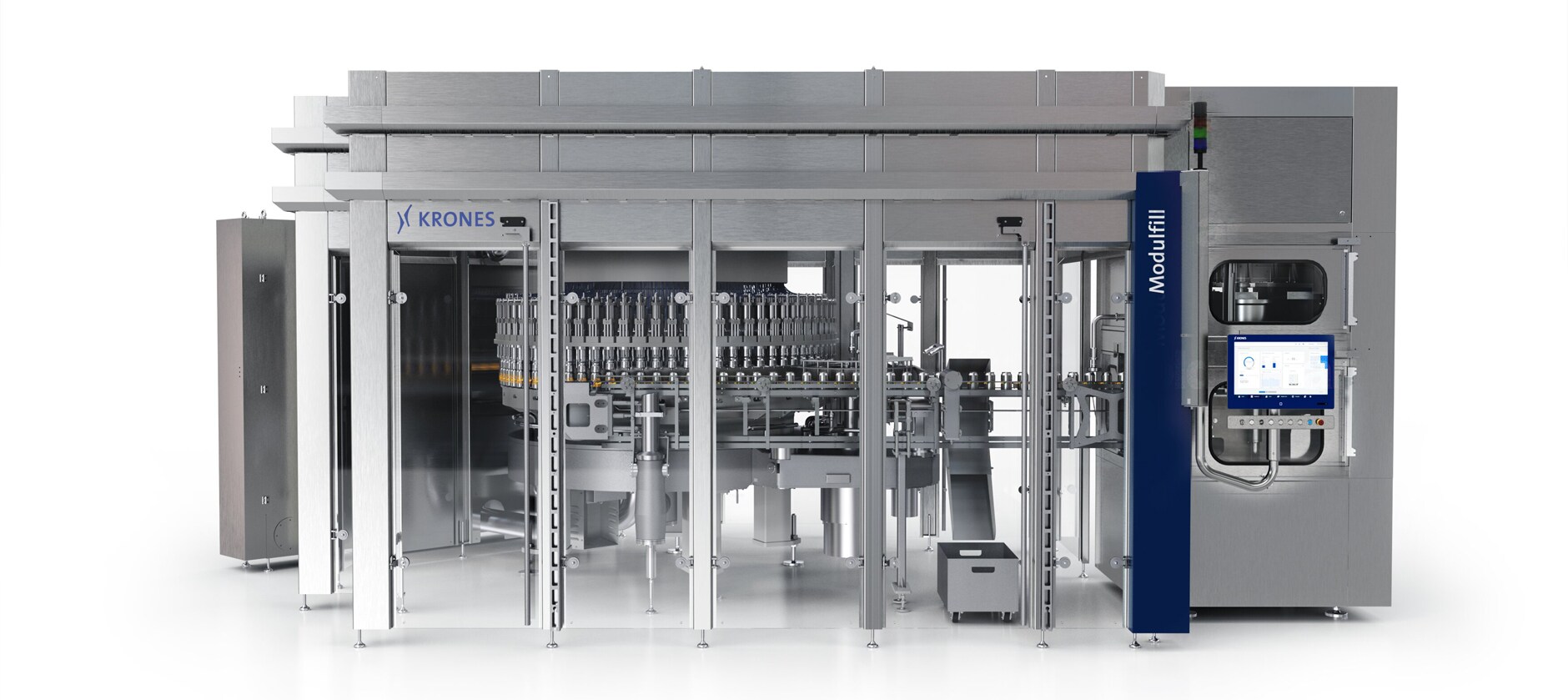

Can filler and seamer from a single source

With isolator on request

The Modulfill Bloc FS-C has already established itself on the market. Now Krones has further developed the block solution. The design incorporating an isolator is particularly suitable for companies that prioritize the highest standards of hygiene during can filling and have sustainability firmly anchored at the top of their corporate philosophy.

For sensitive beverages, such as teas and juices, the Modulfill Bloc FS-C is also available with a small isolator if requested. It does not only score in matters of hygiene, but also requires substantially less space than conventional arrangements.

At a glance

- Block solution comprising can filler and seamer from Krones

- For outputs of up to 135,000 cans per hour

- Processes beer, carbonated soft drinks, water, juice (hot filling) and non-carbonated beverages

- On request: Process area in isolator design in accordance with the dry floor concept

- Saving media thanks to a closed cleaning system

- Increased output thanks to minimised change-over times

Structure in standard design

Design with compact clean room

Ventilation system

Achievements of the Modulfill Bloc FS-C can filler with enviro:

-

Saving media thanks to a closed cleaning system

-

Reduced quantity and variance of the cleaning media

-

Lower filter media requirement thanks to a reduced process space

-

Reduced CO2 consumption thanks to an intelligent process gas control system

Benefits to you – with and without compact clean room

Everything from a single source

With its Modulfill Bloc FS-C, Krones is offering a smart block solution for the filling and seaming of complex beverages.

Minimising the sensitive seaming area

Thanks to the strict separation of the drive area and product area, the sensitive product area can be reduced to a minimum compared to conventional filling technology.

Reliable filling procedure

The filling valve has separate gas channels for pressurisation and depressurisation, ensuring the process steps are precisely controlled. Pneumatic pressing-on and centring ensure precise positioning of the filling valve, thereby increasing process reliability. The hygienic filling valve also meets the highest standards of cleanliness and product safety.

The fastest change-over of its kind

Numerous features ensure that the change-over to new sizes or types is quick and requires little manual intervention:

- Change-over from steel to aluminium cans is possible in a short time thanks to the quickly adjustable quick-set seaming cam: Settings are reproducible and the change-over can be performed in less than five minutes.

- Change-over to other container sizes is also possible in just a few steps thanks to automatic height adjustment system. The entire parameter management and height adjustment of the entire block is done via the filler's HMI, including, for example, the position of the bubble breaker.

- Proven quick-change systems from the Modulfill VFS-C have also been adapted to the Modulseam can seamer.