The question that frequently arises in this context is: What will be product-friendlier and more cost-effective, a continuous or a batch-mode process? Since bright-beer tanks are part of their standard kit anyway, brewers, in particular, often blend their beer-based mixed drinks in batches. And as the portfolio keeps on expanding – to include, for example, the production and flavouring of hard seltzers and other beverages with an intense flavour like (carbonated) soft drinks or fruit juices – a critical appraisal of the production process is definitely worthwhile.

Something everyone is familiar with: An intensely aromatic fragrance permeates the air in beverage plants that work with batch tanks. And precisely this flavour will then be lacking in the product. But just how much flavour is lost?

We sought to answer this very question by running two tests to examine changes in flavour concentrations. The theoretical basis for these tests is that flavour concentrations in the liquid in a vessel and in the gas space above it will reach a state of equilibrium. The bigger the gas space – for instance, when a vessel is only half-full – the more flavour should diffuse from the liquid into the gas space, and would thus have to be calculated as a loss. So much for the theory …

How can I ensure a gentle blending process for my product? Many beverage producers are taking a long, hard look at this issue because one thing is clear: The process chosen has to be designed for resource-efficiency and must not have an adverse effect on the product’s taste and quality.

Test 1: Storing a flavour suspension in stainless steel casks for 24 hours

In the first series of tests, we filled stainless steel casks with orange juice, with a different fill level in each cask. We also added different concentrations of sucrose and ethanol to the juice. We did this because it enabled us to see later on what effect these ingredients have on volatility levels. We took limonene, which is frequently used in the beverage industry, as the reference flavour.

The filled casks were pressurised with nitrogen, so as to minimise oxidation. We then took a starting sample, which was given an airtight seal. 24 hours later, we opened the casks and checked the limonene concentrations. We found that the reference flavour in the liquid had been reduced by up to 86 per cent, as a result of an equalisation of the concentrations in the liquid and the gas space above. We also found that higher sucrose concentrations went hand in hand with an over 20 per cent greater reduction of limonene. The addition of ethanol, by contrast, reduced volatility. Whereas the comparison samples with five per cent ethanol showed smaller losses, the samples without ethanol showed a difference of 20 per cent.

So it can be said that lengthy storage of flavour-intense beverages in not completely filled tanks will result in the loss of considerable quantities of flavour.

The higher the sucrose content, the higher the losses. Ethanol in the beverage, by contrast, reduces losses to some extent since it reduces volatility.

Test 2: 60-minute tank-emptying process

In a second test, we measured the reduction in limonene concentration during an industrial tank-emptying routine because no data had so far been available for flavour-intense beverage types on the quantity of flavours escaping from the product via the gases in a tank’s head space.

To quantify the exact amount of flavour losses, samples in the tank’s outlet were taken throughout the 60 minutes of tank-emptying, and their flavour concentrations measured. As the tank is being emptied and the amount of liquid decreases, gas flows in to fill the space and equalise the pressure in the tank. This gas mixes with flavour vapours escaping from the product.

The results show that the flavour concentration decreases by up to 28 per cent as the tank is being emptied. Accordingly, the product’s concentration of specific flavours is higher at the start of the emptying process than at the end. The product is usually passed from the preparation tanks directly to the filler. So when production starts, the beverage filled is up to 28 per cent more intense in flavour than at the end of production. That is a definite disadvantage of the batch-mode process since a consistent level of product quality cannot be guaranteed.

Loss of limonene (in per cent) during the 60 minutes of tank-emptying

Test results summed up

The questions remain: How critical are flavour losses exactly in batch processing? And what are the possible alternatives or learnings?

With flavour-intense suspensions, such as hard seltzers, beer-based mixed drinks, carbonated soft drinks or juices, the flavour concentration will always change during production. Even while the products are being filled into the tanks and then stored there, considerable amounts of flavour escape into the batch tanks’ head space (Test 1). What is more, the flavour concentration decreases still further while the tank is being emptied (Test 2).

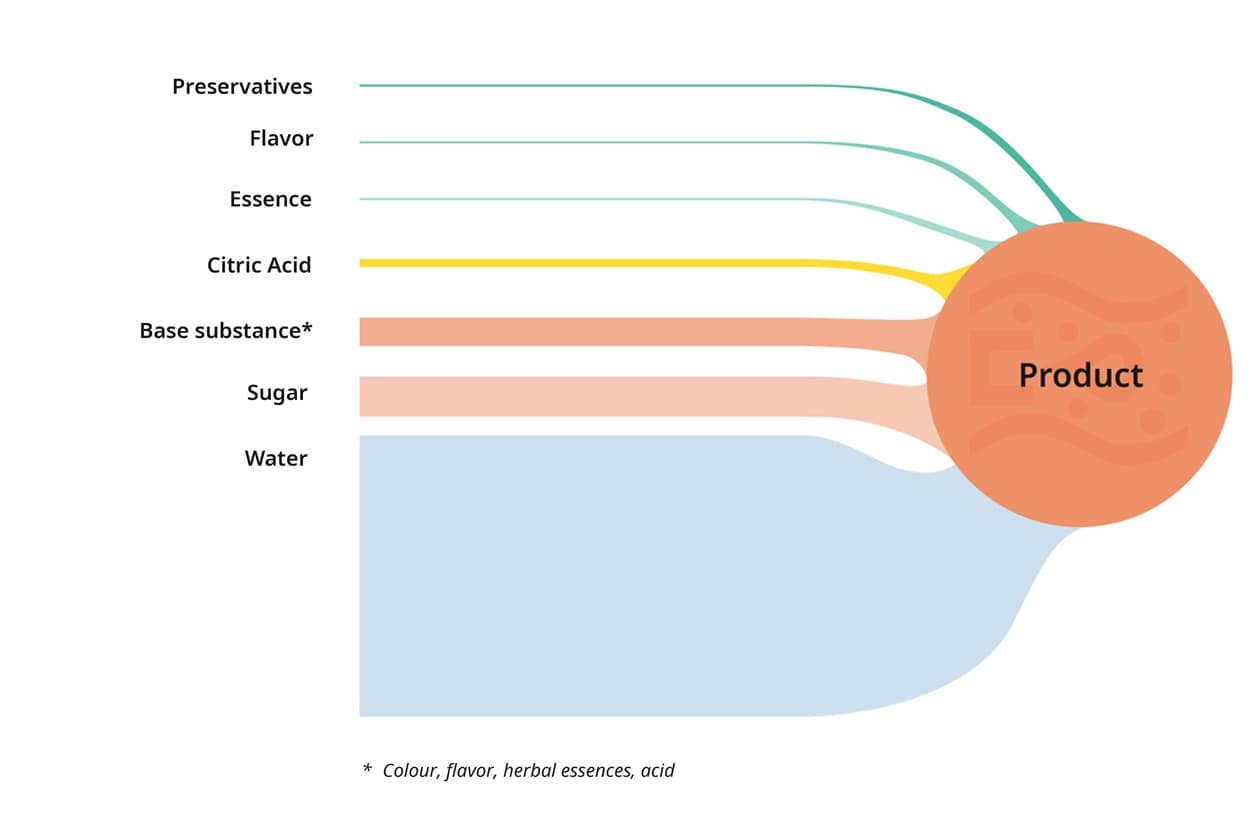

Based on this series of tests, it is recommended to use an inline blending system like our Contiflow for producing flavour-intense beverages. That is because in this system up to eight different components are fed in, each one separately, and blended into the carrier liquid (beer, water) one by one. In this way, the flavours have no opportunity to accumulate in a gas phase, resulting in a consistent flavour concentration in the beverage.

The Contiflow multi-component mixer is also ideally suited for flavour-intense beverages.

What to do, however, if a batch-mode process is unavoidable for reasons of cost and process engineering?

In such cases, it is recommended to incorporate the following learnings from the results in the production process, so as to minimise losses:

- Match tank dimensions exactly to the batch sizes processed

- Wherever possible, fill tanks completely

- Just-in-time production without long tank dwell times

- Reduce the number of tanks and transfer-pumping routines to a minimum

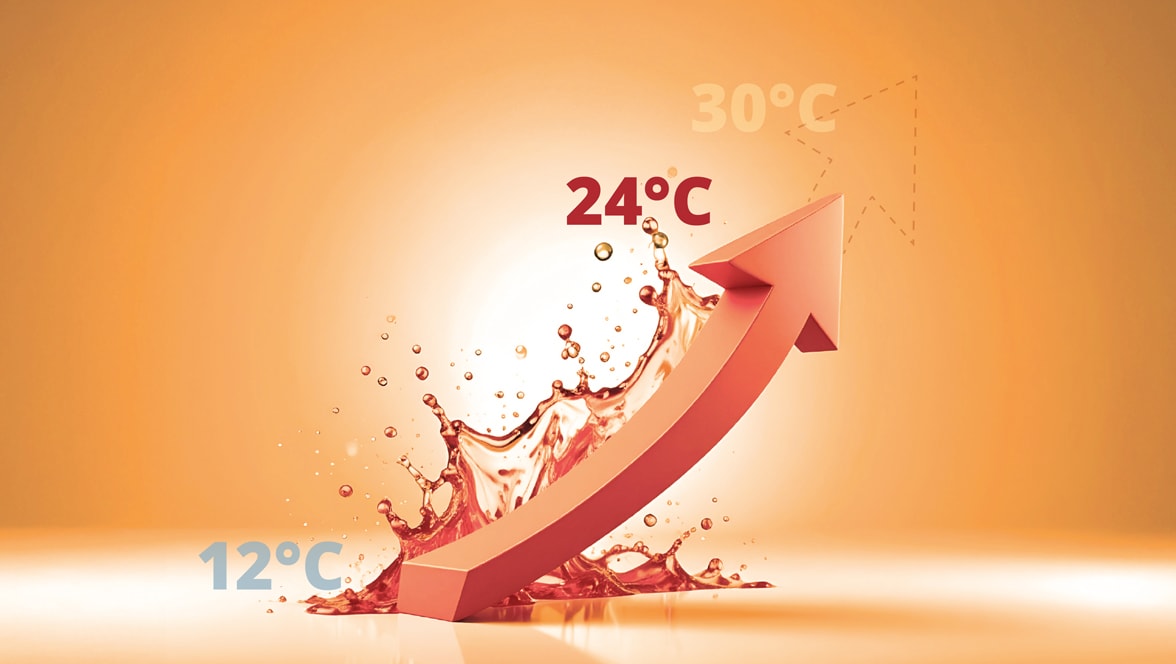

- Depending on the volatility patterns involved: keep production temperatures as low as possible

- No stirring / no transfer-pumping during tank-emptying, so as to limit concentration losses to the top layers of the liquid level