Plzeňský Prazdroj decided to build a new warehouse, in order to keep on using the original recipes and tried-and-tested methods and at the same time facilitate daily routines and guarantee maximum quality levels. The Pilsen brewery had precisely specified requirements for it: The new warehouse should be innovative and fully automated and effectively support the people working there. At the same time, Plzeňský Prazdroj wanted to reduce both costs and CO2 emissions, increase the storage space available and speed up dispatch of its own bottled and canned beers as well as processes in general.

“Plzeňský Prazdroj knew exactly what they wanted: an innovative, automated warehouse that saves costs and reduces the carbon footprint. A customer request that suits us well: cost-cutting and sustainability are two issues frequently required for the solutions we sell,” Ralf John, Head of Technical Operations at System Logistics, explains.

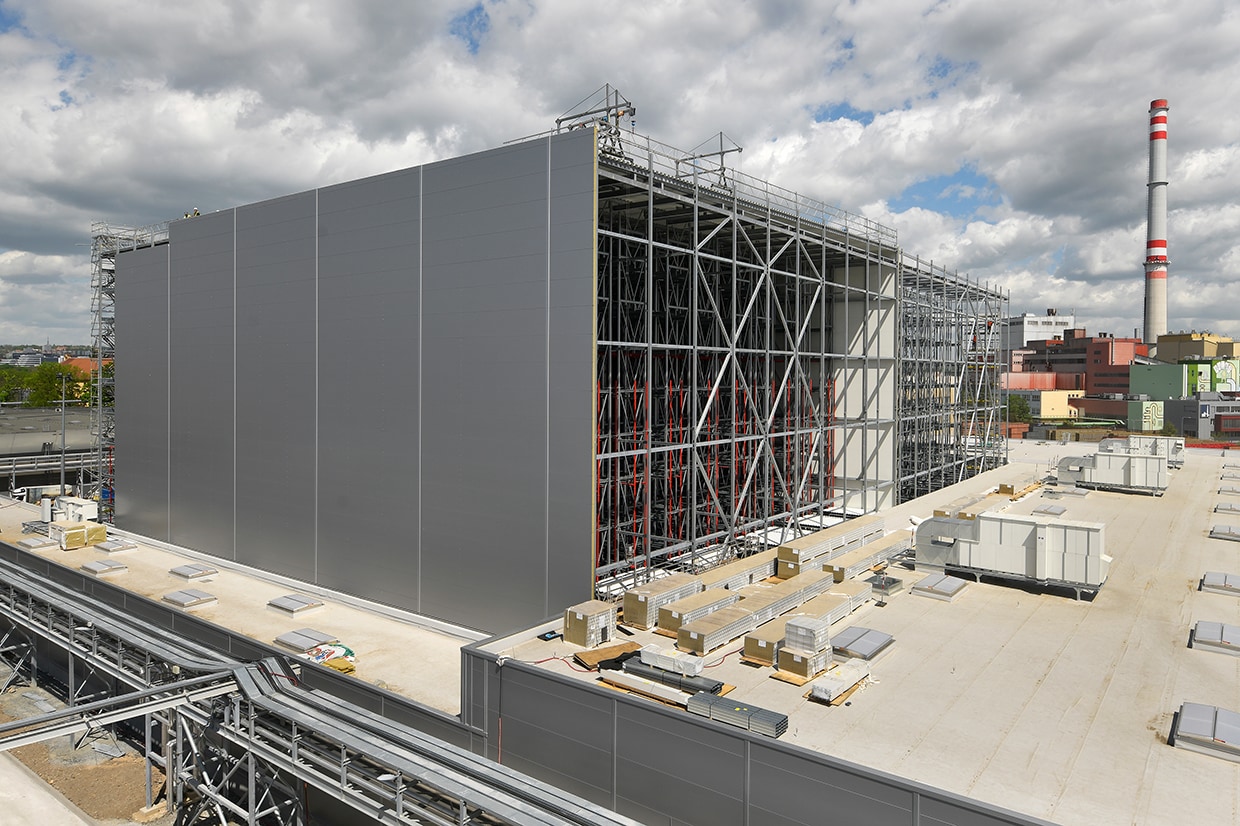

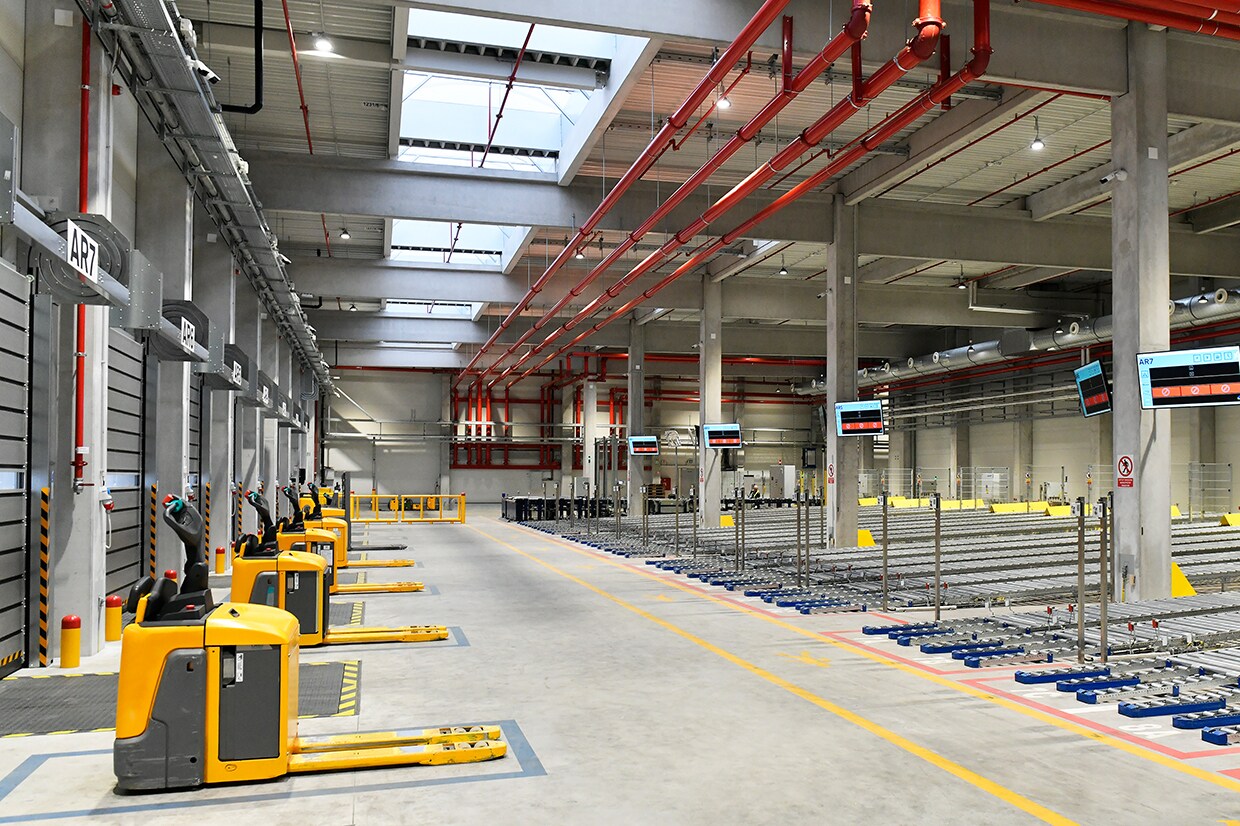

For its new, fully automated warehouse, the tradition-steeped brewery has opted for a solution incorporating the latest state of the art from Krones’ subsidiary System Logistics. The result is highly impressive: a new, self-contained high-bay warehouse measuring 10,000 square metres and providing approximately 16,000 pallet slots. That is roughly equivalent to 18 million bottles of beer, which means the brewery has 20 percent more storage capacity. Ten storage and retrieval units, each of which can transport two pallets, move the pallets into and out of the pallet slots. An automatic monorail with a total of 28 travelling carriages, which is 500 metres long, takes the fulls from the bottling hall to the warehouse, thus saving both space and transport costs.