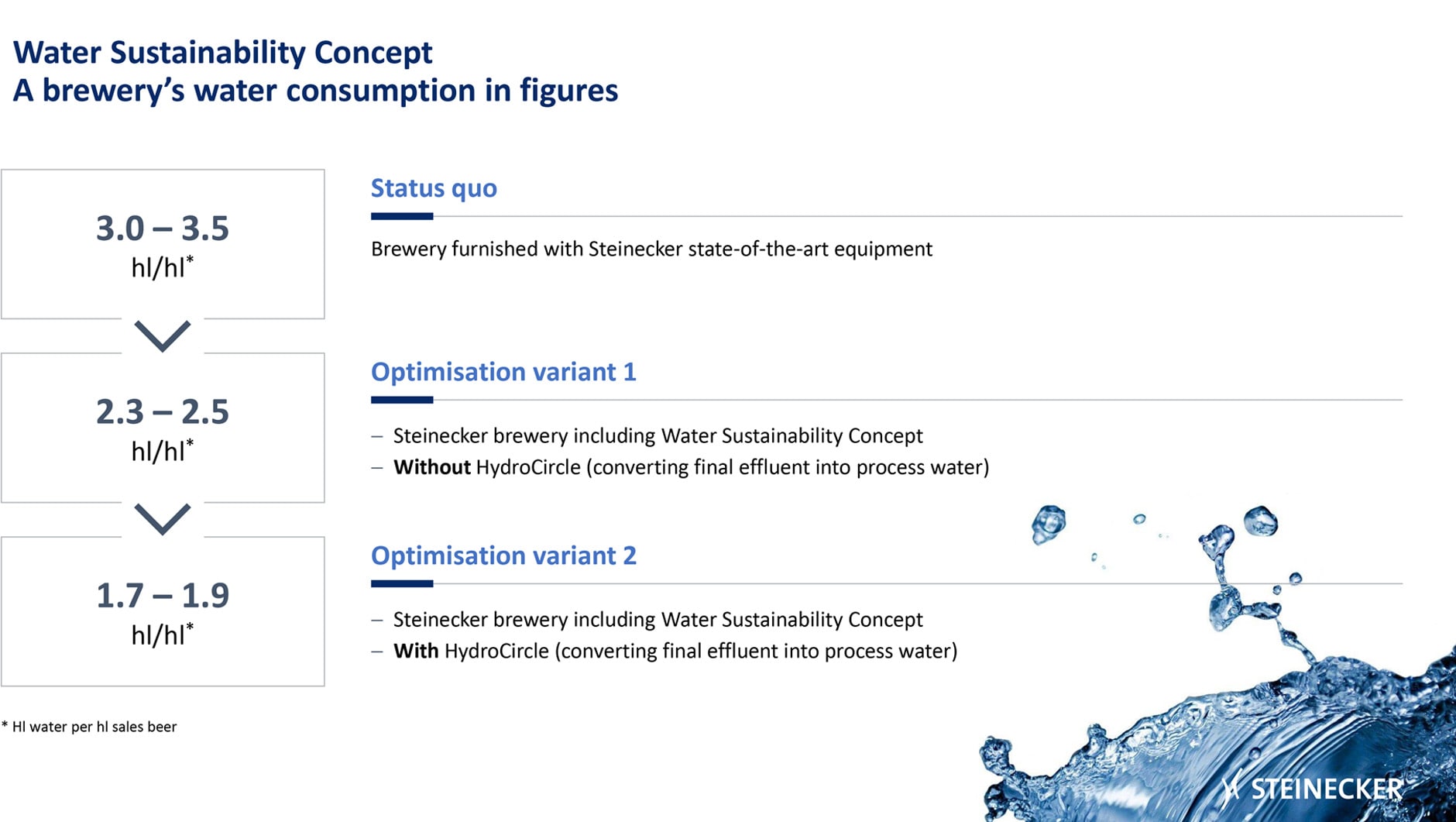

Huge potential savings: halving a brewery’s water use

- Steinecker’s Water Sustainability Concept is a modularised system that combines various options in order to cut a brewery’s water consumption.

- The system’s maximum-savings variant enables water use to be reduced to between 1.9 and 1.7 hectolitres of water per hectolitre of sales-quality beer.

- The Intelligent Water Recovery Concept is a new process for the cold block which makes for water savings of up to 20 per cent.

Designing the production operation for enhanced sustainability, cutting costs, mitigating the challenge posed by dwindling resources: The motivations and reasons prompting breweries to take a long hard look at how much water they use are many and varied. With its Water Sustainability Concept, Steinecker offers an equally varied range of water-saving options for both brewhouse and cellar that provides a custom-fit solution to each brewery’s individual needs.

Steinecker works together closely with the brewery’s team in developing an appopriate system: “The primary consideration for drawing up a suitable Water Sustainability Concept is the investment costs, which have to fit into the customer’s medium- and long-term planning,” explains Jochen Löfflad from Steinecker’s sales team. “That’s why we tackle the issue from two sides: First we tap unused potential with easy-to-implement measures and then we offer innovative technologies for further optimisation. We specify a schedule together with the brewery and implement perhaps two modules in the first year, then another one in the next year – advancing step by step.”

Saving, re-using and treating water

To make sure each solution best fits a brewery’s individual needs, the Water Sustainability Concept comprises a variety of modules. Direct water savings can be achieved by using the high-gravity brewing process or by improving production planning. In a second step, Steinecker offers options for re-using water, such as the Intelligent Water Recovery Concept for the cellar, which serves to collect the brewing liquor expelled from pipes and the flushing water, so it can be used for mashing. Up to 20 per cent water can be saved in this way. With Krones’ HydroCircle, breweries can turn wastewater into process water that can then be used for all CIP routines. All modules can, of course, be incorporated right from the start in greenfield projects, but they are equally well suited for being retrofitted in existing breweries.

Steinecker’s Water Sustainability Concept will pay off for any brewery that chooses to install it, as one look at the water consumption figures shows: The system’s maximum-savings variant, including a water treatment module, enables water use to be reduced to between 1.9 and 1.7 hectolitres of water per hectolitre of sales-quality beer.