New technology – the details

Bottle washer dimensioned for long treatment times

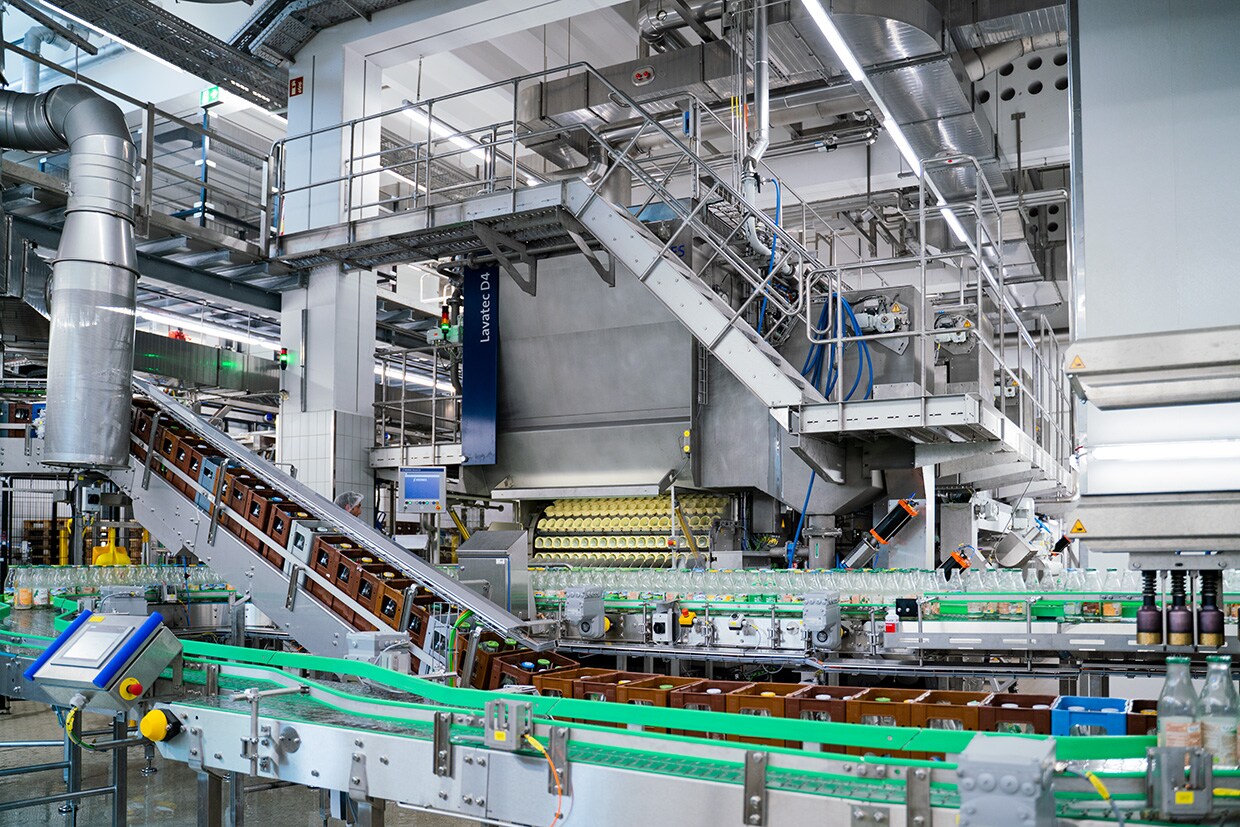

If production is to be divided into a dirty area and a clean area, a double-end bottle washer must be used, in order to provide a spatial separation between bottle infeed and bottle discharge. The new hall is divided into two sections by a ceiling-high wall running over the hall’s entire width. The bottle washer goes through an aperture in this wall sealed off by a stainless-steel frame. That neatly separates the bottle washer’s clean end from the rest of the hall. The Lavatec itself has been specifically designed to comply with the highest hygiene standards and is completely made of stainless steel, including important components. “We are manufacturers of premium products, so stainless-steel surfaces are first choice for our filling lines. That was very important to us. After all, we want to keep the line in good and presentable condition for a long time to come,” explains Paul Althammer. “Krones was able to satisfy this wish. What’s more, it was their overall concept that won us over.” The Lavatec D4 has a fair bit of work to do, in order to remove all the many fat and milk residues from the bottles that enter the machine. So the containers’ dwell time in the caustic section must be correspondingly long. To guarantee these long treatment times, the washer is particularly large. The bottle pre-treatment zone has been designed to prevent severe foaming, despite the lactoproteins’ marked propensity to foam. Hygienic design principles have been rigorously observed throughout the entire line: There are no corners or edges where residues might collect, and the discharge profiles guiding the clean bottles onto the conveyor belt are made of biocidal plastic, thus avoiding any recontamination. The Lavatec works with two caustic baths. The first one rinses off most of the soiling, and therefore the second caustic bath is hardly soiled at all. This two-chamber system substantially reduces the dirt load in the wastewater tank. Overall, the new bottle washer consumes half the amount of fresh water previously needed and significantly less chemicals.